Introduction

Additive manufacturing, better known as 3D printing, is an emerging application that is finding an expanding purpose in the manufacturing process. Once primarily used for quickly making prototype parts, 3D printing is now also used to digitize workflow and manufacture production quality final products. There are many different types of 3D printing methods used to physically create a desired object. In this application note, we will focus on powder bed 3D printing, which utilizes heat from a laser-beam, electron-beam or a thermal printhead to melt material together and create a solid object.

To optimize 3D printing performance, the laser- and electron-beam optics must be efficiently cooled. Precise cooling is also needed to help control the viscosity of the liquid powder as it is dispensed onto the surface of the thermal printhead. Power sources often need to be cooled as well. Refrigerated chiller systems are the preferred method for cooling the thermally sensitive additive manufacturing system, while thermoelectric coolers can also be used for spot cooling components.

Application Overview

Additive manufacturing is a process that creates a desired object by stacking (printing) layer after layer of melted plastic resin or metal to create a solid three dimensional part. It starts with a digital file created in CAD (Computer Aided Design), a 3D modeling program or a 3D scanner. Software takes the digital file image and slices it into thousands of horizontal layers to create a template for the 3D printer to follow. Powder bed 3D printers use a laser beam, electron beam, or a thermal heated printhead to melt the plastic resin or metal material that is immediately laid down, layer by layer, on a printing bed until the 3D object is completed.

Products of complex design can now be easily conceptualized and manufactured with great precision by additive manufacturing. As a result, a wide range of industries are now implementing additive manufacturing technologies. The medical industry is using 3D printing to make casts, prostheses, hip replacements and more. The aerospace and automotive industries are making new and retrofit light weight parts. Also, consumer goods are increasingly manufactured using additive manufacturing methods.

According to a research report by Research Cosmos, the global additive manufacturing market is predicted to reach USD 36.61 Billion by 2025, up from USD 8.4 billion. This includes a CAGR of 17.7% during the forecast period 2019 - 2025. In addition, as costs of 3D printers continue to decrease, many forecasters predict additive manufacturing to be commonplace for home use.

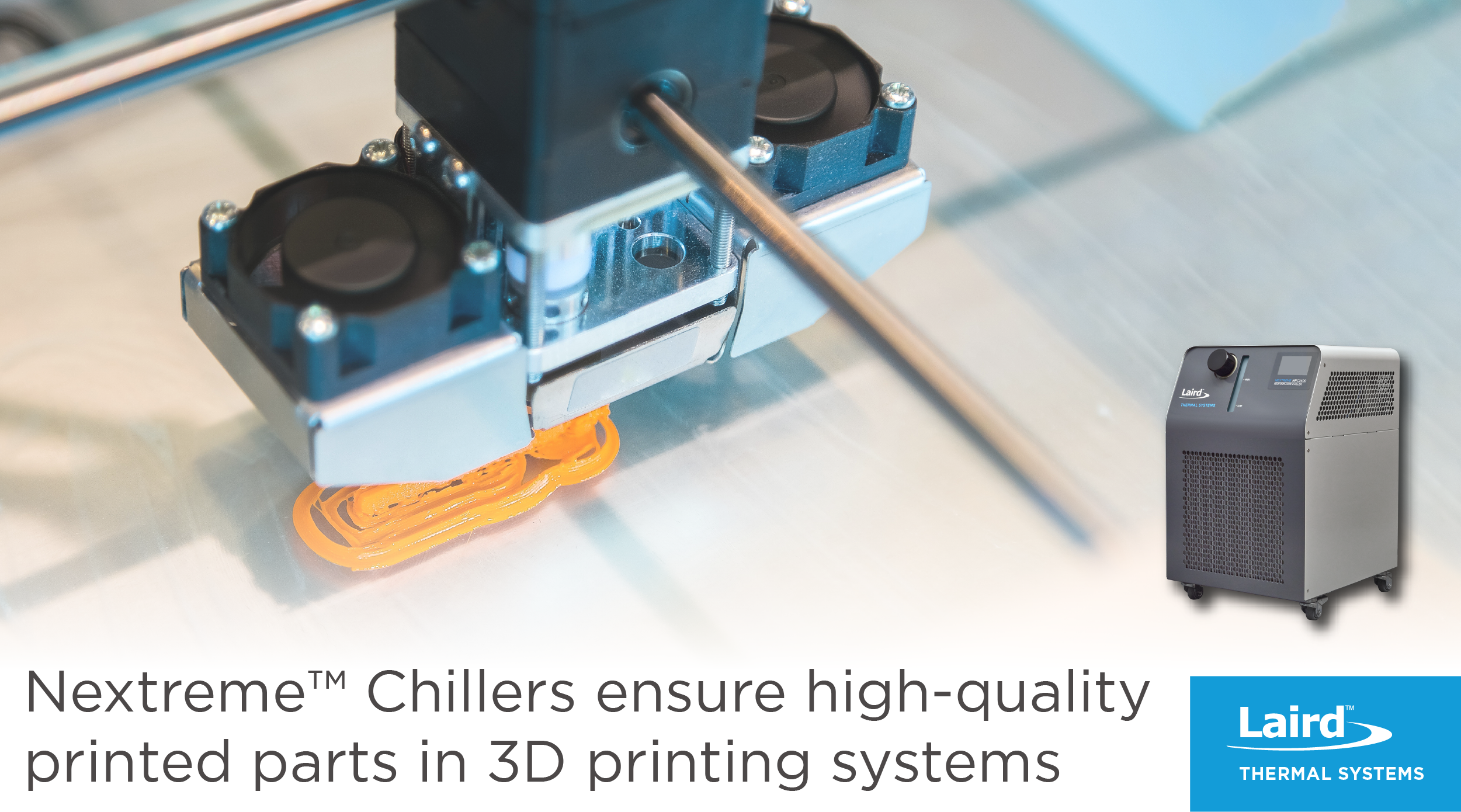

3D Printing Machines require a cooling solution to ensure

long operation life and maximum performance.

Application Challenges

Temperature control is essential in additive manufacturing applications for various reasons. Laser and electron beam optics must be thermally protected to ensure a longer operating life and superior performance to properly melt printing materials. Depending on the material that is being used for printing, heat generated from the laser or electron beam can be many kilowatts. For optimal performance, the laser optics typically require a stable operating temperature of 20°C ± 0.1°C, while ambient temperature may fluctuate between 23°C to 35°C in a room temperature environment. Laser-beam and electron-beam power supplies often need to be cooled as well, as overheating degrades the reliability and operating lifetime.

Thermal printhead nozzles must also be appropriately cooled, as to only melt the plastic resin or metal, and not the electronics doing the 3D printing. For printhead nozzles, temperature control is also important for melting the precise amount of material and maintaining appropriate material viscosity. If the nozzle runs too hot, too much material will be melted and printed, affecting the quality and precision of the 3D object. Excess material can also clog or jam the nozzle as it cools. A nozzle that is not hot enough will also not print correctly, as the material viscosity will be too great. This can also clog the nozzle during printing.

Temperature control is also crucial when printing smaller and more complex pieces. 3D printed objects with meticulous detail must be cooled quickly to ensure the integrity of the design. Whether the Powder bed 3D printer uses a laser beam, electron beam or thermal printhead nozzle, waste heat must be managed and dissipated efficiently in order to guarantee 3D printing quality. Moving heat away from sensitive electronics must be accomplished with a thermally efficient solution. Manufacturers of power hungry systems, like additive manufacturing equipment, are tasked with using components that increase performance while reducing energy consumption.

In addition, it is desirable to have thermal management systems that provide quieter operation including lower noise and vibration. Loud, vibrating machines can create an unpleasant and dangerous work environment. Equipment cooling units can play a significant role in the decibel level on a manufacturing floor.

Many governments, especially in North America and the European Union, are requiring OEMs to phase out the use of traditional high global warming potential (GWP) refrigerants. Traditional compressor-based systems utilize environmentally harmful HFC refrigerants like R134a and R404A. Modern compressor-based systems now use a variety of natural refrigerants including R744 (carbon dioxide), R717 (ammonia), R290 (propane), R600a (Iso-Butane), and R1270 (propylene). Natural refrigerants do not come without some complications. They can be difficult and dangerous to work with, as many are flammable. However, natural refrigerants are significantly better for the environment, and are approved for use by all government agencies.

Comparing Cooling Technologies

Two methods commonly used to cool 3D printing laser systems are compressor-based refrigeration systems such as chillers and an ambient liquid loop system that utilizes a thermoelectric cooler. Unlike liquid-to-air heat exchangers, both these systems have the ability to cool well below ambient temperatures.

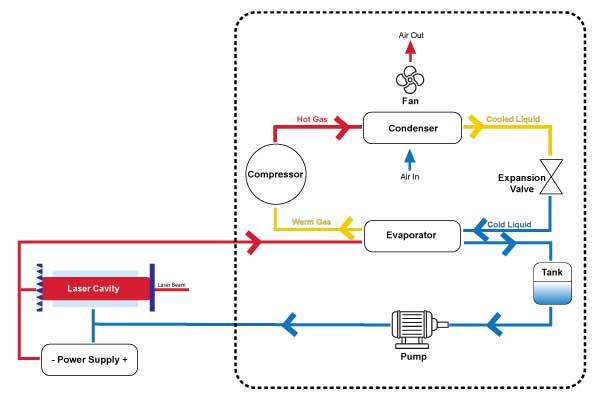

Compressor-based refrigeration systems deliver a higher coefficient of performance (COP) compared to ambient liquid loops using thermoelectric coolers. For example, if the application requires cooling a heat load of 3kW, a standard compressor-based refrigeration system typically requires around 1kW of energy to properly cool it. Chillers operate via a compressor-based refrigeration unit that cools outbound fluid (coolant), which is then routed to the sensitive laser electronics to provide cooling.

Compressor-based refrigeration systems control the temperature of water or water with glycol (antifreeze) in a liquid circuit, which is efficient when cooling 3D laser applications. The coolant is recirculated using a high reliability pump. Heat from the coolant is absorbed by a durable, compressor-based system and dissipated to the ambient environment.

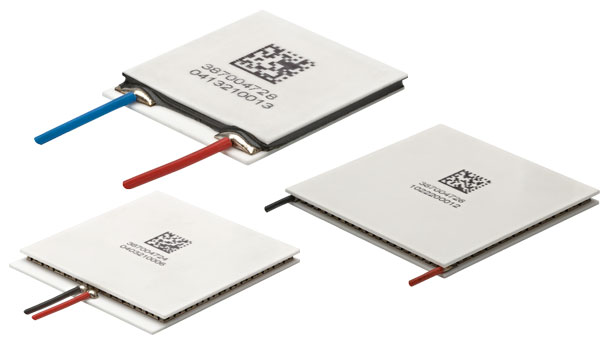

Another thermal solution is ambient liquid loops that use thermoelectric devices for precise spot-cooling. By utilizing the Peltier effect, thermoelectric coolers can maintain stable temperatures of sensitive electronics below their maximum operating temperature. Thermoelectric coolers used for this application have a heat-pumping capacity up to 296W with a maximum temperature differential (ΔT) of 72°C to. In this application, a large amount of heat travels through a very small space. The thermoelectric coolers typically used are 25x25, 30x30 or 52x52 millimeters.

Compared to other technologies thermoelectric coolers are often a more cost effective solution offering high reliability and long-life operation with almost no maintenance.

Recirculating Chiller Solution

The Nextreme™ Recirculating Chiller Platform from Laird Thermal Systems offers reliable and precise temperature control for additive manufacturing applications including powder bed 3D printing. The Nextreme™ Recirculating Chiller Platform is able to efficiently control the temperature of all sensitive electronics within the 3D printing system, including the power source, the laser or electron beam optics, and the thermal print head. In addition, a chiller can be used to quickly cool smaller and/or highly detailed 3D printed objects to preserve design integrity.

The Nextreme™ Recirculating Chiller Platform utilizes high-performance variable speed motors, offering low noise operation and up to 50% lower energy consumption compared to conventional compressor-based systems. By using environmentally-friendly R513A refrigerant, the Nextreme™ Chiller delivers similar performance with half the Global Warming Potential (GWP) compared to traditional hydrofluorocarbons (HFC) refrigerants.

The chiller platform maintains temperature stability to within ±0.1°C of the set point temperature. The unit can heat and cool fluid to maintain a thermal set point, offering greater flexibility and reducing the need to implement a separate heating element. 3D printing machines benefit greatly from the precise temperature control, ensuring optimum performance of the power source, optics and thermal printing head.

Featuring an LCD touchscreen display, the Nextreme™ Chiller is designed with the end user in mind. It allows the user to control temperature setpoints, flow and alarm settings, coolant type, while coolant level is easily monitored via the indicator window on the front panel.

For maximum uptime, the Nextreme™ Chiller features the optional “hot swappable” 5-micron water filter for filtering particulates from the coolant circuit. This means that maintenance can be scheduled at any times as there is no need to shut down the unit during maintenance. With no moving parts, an optical fluid level sensor offers improved reliability and increased uptime when compared to chillers that use mechanical float switches. The programmable alarm alerts the user when fluid level falls below acceptable operating conditions. To prevent damage to equipment in high pressure operating conditions, the chiller senses the supply fluid pressure and will alert users when low- or high-pressure limits have been exceeded.

The Nextreme Chiller Series is available in three series types. The Performance Series features premium components available in three standard versions; 1600, 2800, and 4900 Watts. The Value Series is a cost-effective solution with simpler components and control system available in three standard versions; 1200, 2700, and 4800 Watts. The Natural Refrigerant Series – using R290 refrigerant is compliant with foreseeable future regulations. All these models can be configured to meet specific application requirements.

The Nextreme™ Recirculating Chillers offer precise temperature control

for additive manufacturing applications.

Thermoelectric Cooler Solution

For lasers with a footprint smaller than 100 x 100 mm, thermoelectric coolers are often mounted directly onto the exterior of the laser for temperature stabilization. Thermoelectric coolers for laser and electron beam cooling often have high heat pumping per square area to match the generated heat. It is common to use thermoelectric coolers with heat flux densities of up to 13 Watts per cm2 for these types of applications. Thermoelectric coolers operating at these high heat pumping levels often exceed the ability of a heat sink and fan to dissipate heat into the surrounding environment. Therefore, an ambient liquid cooling system and cold plate is a better option as it can minimize space constraints at the source, while routing heat out to an area where there is more space to exhaust heat into the ambient environment. For greater heat loads, multiple thermoelectric coolers in an array may be required. When using multiple arrays it is important to lap surfaces of the thermoelectric coolers so the thicknesses are within tight tolerances during mounting to heat exchanger. This is important in order to minimize air gap between the thermoelectric coolers and the heat exchanger.

The UltraTEC™ UTX Series from Laird Thermal Systems is ideal for spot cooling of additive manufacturing applications. This series utilizes advanced thermoelectric materials for higher heat pumping capacity compared to standard semiconductor materials and offers a 10% boost in heat pumping capacity over standard thermoelectric coolers. The thermoelectric cooler features a higher thermal insulation barrier that delivers greater temperature differential with a ΔTmax = 72K.

The UltraTEC UTX Series can cool well below ambient and dissipate heat away from sensitive components of 3D printers. The largest model in the UltraTEC UTX Series thermoelectric cooler family achieves a heat pumping capacity of up to 296 Watts. Form factors of this series ranges from 25 x 25 mm up to 52 x 52 mm. With their solid-state construction, thermoelectric coolers offer reliable operation with almost no maintenance, reducing the total cost of ownership.

Laird Thermal Systems™ UltraTEC UTX Series is ideal for spot cooling of 3D printing systems.

Conclusion

There are many different additive manufacturing technologies used to create 3D objects. However, all different techniques require advanced cooling to increase the operational life of components and systems and ensure high quality of the 3D printed object. Powder bed 3D printers can use a laser beam, electron beam or thermal print head to melt plastic resin or metal used when printing. Stabilizing the operational temperature of these systems is vital to the operation and uptime of the 3D printing machine. Several thermal management technologies that can be used to maintain thermal control of 3D printers. The UltraTEC UTX Series thermoelectric cooler utilizes advanced thermoelectric materials for higher heat pumping capacity compared to standard coolers. With no moving parts, the solid-state device can cool electronics well below ambient temperatures and can significantly reduce maintenance requirements and operation costs when compared to other cooling technologies. However, the compact Nextreme™ Recirculating Chiller platform offers a higher coefficient of performance that delivers efficient, low power thermal control. The chiller platform provides higher efficiency and reliability than air-based heat exchangers and thermoelectric devices — all in a smaller and lighter package compared to previous versions.

To learn more about the Nextreme™ Recirculating Chiller Platform, visit

http://www.lairdthermal.com/nextreme

More information on the UltraTEC UTX Series can be found by visiting

www.lairdthermal.com/utx-series