Introduction

Industrial lasers come in various sizes and power levels. Brazing, metal cutting, deep metal welds and metal cleaning require high-power lasers while printing & marking, soldering, plastic welding and laser powder remelting use low power lasers. Temperature stabilization is key to maintaining peak performance for any industrial laser system. For high-power lasers, a robust liquid cooling solution will most likely be required (see application note on cooling high-power lasers). In this application note we will be focusing on lower power lasers, which typically use thermoelectric recirculating chillers.

Application Background

Passive cooling solutions such as heat sinks can be sufficient for helium-neon or argon-ion laser systems. However, passive systems are insufficient for cooling sensitive electronics and laser systems larger than 10 Watts will most likely need an active cooling system. The design of an effective closed loop cooling system where heat is absorbed by a coolant can be fairly simple. Because the coolant does not come in contact with the environment, it remains clean and uncontaminated.

Traditionally, compressor-based systems have been used to cool laser systems. However, enhanced thermoelectric cooling solutions have become more popular for spot cooling of sensitive optoelectronic components used in laser systems.

Industrial laser applications require precise temperature control for optimum performance and long-life operation.

Laser Design Challenges

Waste heat in low-power laser systems ranges from tens up to hundreds of watts. A cooling system is required to efficiently dissipate heat to the ambient environment.

Temperature Control

Optics in laser systems must be kept at a nominal temperature between 20 to 35⁰C with a temperature stability of ±0.5°C. Precise temperature control will eliminate laser power fluctuations to ensure a stable laser wavelength for maximum precision. Cooling of sensitive optoelectronic components will also extend the operational life, maximize uptime and lower the total cost of ownership by increasing the mean time between failures (MTBF).

Noise & Vibration

Low powered laser systems require a cooling system to enable a steady flow coolant to the temperature sensitive components without pulsation. Temperature fluctuations can distort laser performance as well as the operational lifetime of components. Larger compressor-based systems are typically noisier and use larger pumps which tend to pulsate. Thermoelectric-based recirculating chillers are equipped with smaller pumps providing lower pulsation.

Portability

Modern laser cooling systems are designed for portability to enable cooling of multiple pieces of equipment on the manufacturing site. Traditional compressor-based systems are often bulky and heavy, which makes them challenging to move. Thermoelectric-based chillers are much lighter, typically less than 20 kg’s and can easily be moved.

Environmental Regulations

Environmental regulations continue to phase out the use of ozone depleting refrigerants tied to global warming. Older compressor-based systems utilize environmentally harmful HFC refrigerants including R134a and R404A. Although modern compressor-based systems now use a variety of natural refrigerants, which is better for the environment, they have their own complications, including flammability. Because thermoelectric-based chillers do not use any harmful CFC refrigerants, providing zero global warming potential, they are the “greenest” option.

Thermoelectric Chiller Solutions

Recirculating chillers are a better option than passive solutions such as heat sinks and fans because of their ability to cool well below ambient temperatures. A liquid-based cooling system is more efficient than an air-based system at dissipating heat away from the laser system due to the thermal conductivity of the coolant versus the air.

Providing high reliability and minimal maintenance without using any harmful refrigerants, thermoelectric chillers are becoming more popular. In addition, thermoelectrics have the ability to both heat and cool, providing better temperature stability for industrial laser applications. The plug and play design provides quick and easy installation to any industrial laser system.

How Does It Work?

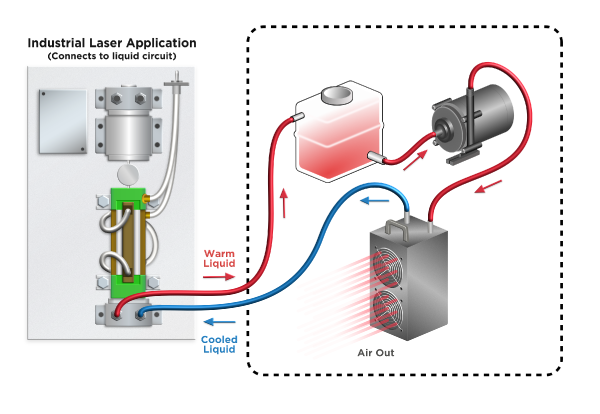

Heat generated by the laser is absorbed by a liquid coolant (ethynol glycol water mixture) that flows to a reservoir tank by using a pump. The pump pushes coolant through a Liquid-to-Air thermoelectric engine, which cools the coolant circuit while dissipating heat into the ambient environment. The coolant will then flow back to the laser system at the desired temperature setpoint.

Laird Thermal Systems Solution

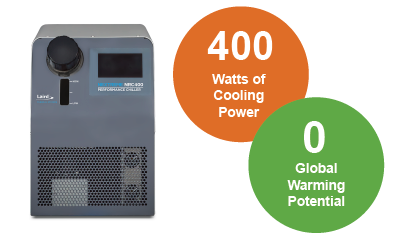

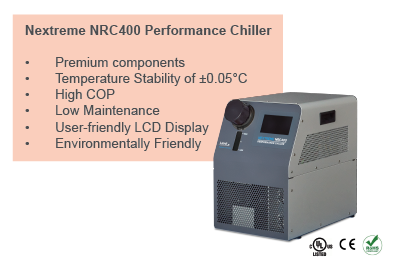

The Nextreme™ NRC400 is a next generation benchtop recirculating chiller that combines advanced thermoelectric cooling with high performance heat exchanger technology. The compact unit utilizes thermoelectric coolers with advanced thermoelectric materials to deliver 400 Watts of cooling power, while offering precise temperature control stability to within ±0.05°C under steady state conditions. Temperature setpoints and alarm features are easily controlled from the intuitive touchscreen display. The NRC400 is a semi-closed system equipped with a large reservoir tank requiring less refilling during operation.

Compared to previous versions, the NRC400 offers a higher coefficient of performance (COP) and a quieter operation. Because thermoelectric chillers utilize solid-state thermoelectric coolers, the system has few moving components resulting in less down time for maintenance requirements.

The portable NRC400 weighs only 21 kg, which is significantly lighter and smaller than traditional compressor-based cooling systems. Because it can easily be moved from one industrial laser machine to another, the NRC400 reduces the number of cooling systems needed in the facility.

The environmentally-friendly NRC400 uses no harmful CFC refrigerants resulting in zero global warming potential. Units operate on a universal power supply from 115V to 230V making it easy to source one-part number globally.

Conclusion

Processing and manufacturing industries are looking for ways to lower costs while increasing throughput and quality. Although compressor-based refrigeration systems have long been used to cool laser systems, portable thermoelectric-based chillers providing more reliable and precise temperature control have grown in popularity. The NRC400 from Laird Thermal Systems is a next generation recirculating chiller offering a easy to use cooling system with more features. By utilizing advanced thermoelectric cooler technology, the NRC400 delivers better temperature stability, higher COP and lower noise operation than previous models.

More information on the NRC400 can be found on the Laird Thermal Systems website.