Introduction

Machine vision is the replacement of human examination, assessment and decision-making with video hardware and software systems. The technology is often used for vision inspection, quality control, robotics, wire bonding and down-hole applications where machine vision systems obtain data from analyzing images of a specific process or activity.

In addition to inspection systems, machine vision technology is enabling sophisticated object detection, recognition and collision avoidance systems for next-generation autonomous vehicles, drones and robotics. Machine vision also plays a role in many artificial intelligence and machine learning applications such as facial recognition.

Nothing can be achieved in a machine vision application without the successful capture of a very high image quality. Utilizing temperature-sensitive imaging sensors and cameras, machine vision systems require active cooling to deliver optimal image resolution independent of the operating environment.

Machine Vision Systems require active cooling to achieve the optimal image resolution.

Thermal Challenges

Machine vision applications use two types of sensors to convert photons to electrons for digital processing; charge-coupled device (CCD) and complementary metal-oxide semiconductor (CMOS) sensors. As the temperature of the sensor assembly increases, image resolution is negatively affected by thermal noise. This can occur in many machine vision applications where environmental conditions or the heat generated by surrounding electronics exceeds the maximum operating temperature of the sensor.

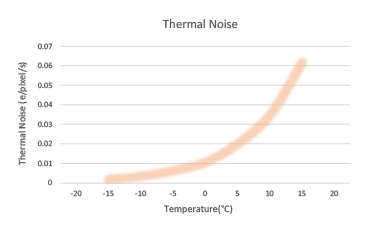

A rough estimation below shows that dark current doubles for every 6°C rise in temperature. A 20°C drop in temperature could reduce the noise floor by 10dB, thereby improving dynamic range by 10 dB. In outdoor environments, temperatures can exceed 40°C. To prevent image quality from deteriorating, solid-state Peltier coolers can be used to reduce the sensor’s temperature below its maximum operating temperature and maintain high image resolution.

Figure shows that dark current doubles for every 6°C temperature rise in imaging sensors.

Spot cooling CCD and CMOS sensors in machine vision applications can be challenging. The addition of Peltier cooling devices will increase the size, cost, weight and complexity of the imaging system. Cooling of the imaging sensors can result in condensation due to surfaces exposed to temperatures below dew point. However, many vision systems are contained in a vacuum environment with insulated surfaces on the exterior to prevent condensation build up over time.

Passive cooling can be quite inefficient for CMOS sensor applications due to airflow limitations. This can result in a design that cools slightly above the ambient temperature, which may be above the maximum operating temperature of the CMOS sensor. This is common for outdoor applications, where active cooling is often required. When using active cooling solutions such as Peltier devices, a heat exchanger is most likely needed to dissipate heat into the air environment. Fan cooling or even liquid cooling is required to sufficiently dissipate heat and lower the thermal resistance of the hot side heat exchanger.

In addition to thermal requirements, design considerations are needed to minimize thermal shorting. This is the result of the cold side surfaces touching the hot side surfaces, causing the Peltier cooler to draw more current in order to deliver the same cooling performance. When designing the optimal cooling solution in machine vision systems the assembly needs to be in consideration. For example, outgassing is not acceptable because it can coat the imaging sensor optics. It is therefore vital to properly select thermal interface materials between the Peltier cooler and the sensor with low outgas characteristics.

Thermal Solutions

The image quality of CCD and CMOS sensors is typically affected at temperatures in the 50ºC to 60ºC range depending on the quality of the sensor. For indoor applications, it may be sufficient with a free convection heat sink with interface material and adequate airflow to cool a CMOS sensor to just above ambient. However, the heat sink need to have maximum surface-to-air contact in order to reduce the overall thermal resistance. Typically, space constraints make it difficult to accommodate the heat sink needed and forced air is required to keep the temperature just a few degrees above ambient.

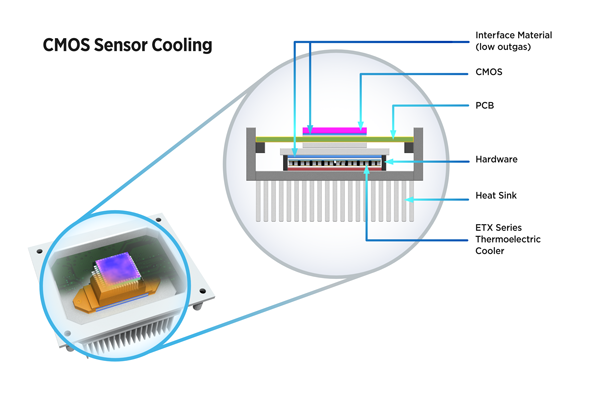

For most outdoor applications these passive thermal solutions will be insufficient. Heat from surrounding electronic components will most likely exceed the maximum temperature limit of the CMOS sensor and require a Peltier cooling solution. The thermoelectric cooler creates a temperature differential across the module, lowering the temperature of the critical sensor by as much as 50°C from the hot side temperature of the heat sink. If the hot side heat sink is at 90ºC, the Peltier cooler can cool the CCD or CMOS sensor to a temperature of 40ºC.

CMOS sensors in machine vision systems require active cooling to deliver optimal image resolution independent of the operating environment.

Thermoelectric Coolers

Thermoelectric coolers use the Peltier effect to create a temperature differential (ΔT) to transfer heat from one side of the sensor to the other. Thermoelectric coolers are integrated directly into the sensor assembly and typically require a heat sink or other heat exchanger to dissipate heat into the surrounding environment.

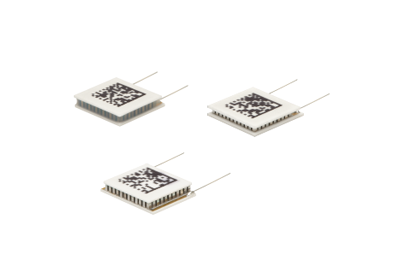

OptoTEC™ OTX/HTX Series

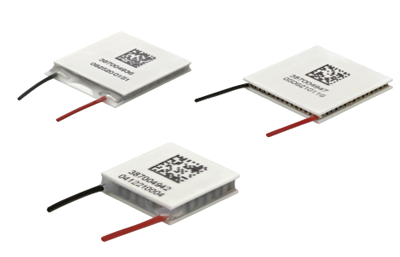

By combining a small geometric footprint of less than 13X13 mm with advanced thermoelectric materials, the OptoTEC™ OTX/HTX Series offers high heat pumping capacity and improved temperature stability for machine vision applications with tight geometric space constraints. The robust construction allows it to survive in high temperature environments and the product series is validated to withstand harsh environmental testing based on Telcordia GR-468 CORE requirements.

The OptoTEC Series is offered in two versions; OTX and HTX. The OptoTEC OTX uses SbSn solder, enabling a maximum operating temperature of 120°C and a melting point of 232°C for reflow purposes. Utilizing AuSn solder, the OptoTEC HTX thermoelectric cooler survives in extreme temperatures up to 150°C and has a melting point of 280°C. Custom configurations are available to accommodate metallization, pre-tinning, ceramic patterns, and solder posts.

The miniature OptoTEC™ OTX/HTX Series offers high heat pumping capacity for machine vision applications with tight geometric space constraints.

HiTemp ETX Series

Supporting machine vision applications operating in temperatures ranging from 80°C to 150°C, the new HiTemp ETX Series offers cooling capacity from 7.7 to 322 Watts in a compact form factor. The thermoelectric cooler is assembled with advanced thermoelectric materials. When compared to standard thermoelectric coolers, this series features an improved thermal insulating barrier creating a maximum temperature differential (ΔT) of 83°C. In high temperature environments, the enhanced module construction prevents performance degradation in high temperature environments such as machine vision systems. To meet a broad range of emerging applications, the HiTemp ETX Series offers more than 50 models with a wide variety of heat pumping capacities, form factors and input voltages.

The HiTemp ETX Series is available in cooling capacities ranging from 7.7 to 322 Watts

Conclusion

The evolution of machine vision systems beyond traditional inspection systems requires high-resolution CCD and CMOS imaging sensors. The new HiTemp ETX Series of Thermoelectric coolers keep mission-critical imaging sensors below their maximum operating temperature to ensure the highest image resolution for object detection, recognition and collision avoidance systems in next-generation autonomous vehicles, drones and robotics.

Laird Thermal Systems has the design, prototyping, testing and global manufacturing services to help integrate Peltier cooling systems into machine vision applications. Our engineers partner closely with customers throughout the entire product development lifecycle to reduce risks and accelerate time-to-market for emerging applications.

Visit our website to find OptoTEC OTX/HTX Series and HiTemp ETX Series.