Overview

Refrigeration units are vital to the food and beverage industry to ensure proper storage temperatures and to maintain health and safety regulations. Refrigeration and cooling methods continually advance to simplify beverage transportation and beverage dispensing. From small consumer appliances used to refrigerate milk, coffee, beer, juice, soda and wine, to large mobile carts that transport food from a kitchen to a catering point, refrigeration ensures beverages are consumed at appropriate safe temperatures. Refrigeration units utilizing thermoelectric coolers are an alternative to conventional compressor-based systems for beverage cooling. Because a thermoelectric cooler assembly is compact, robust, and completely solid-state, the inherent reliability of such a system is attractive to engineers and end-users alike.

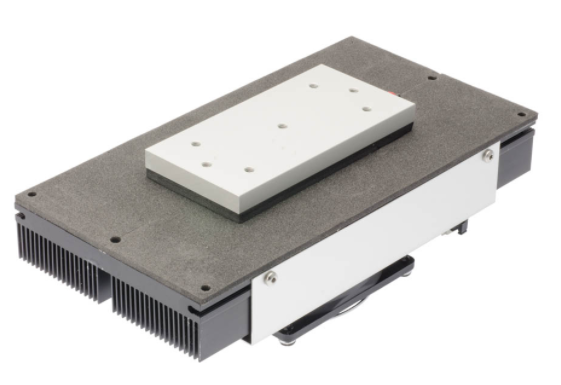

The thermoelectric cooler assembly units are designed with size, efficiency, cost, and continuous reliable operation in mind. Additional design factors include speed of cooling response, temperature stability, and resistance to damage by moisture intrusion. Thermoelectric cooler assemblies enable food/beverage storage compartments to stay cold or frozen at precise temperatures. Thermoelectric cooler assemblies can even enable different compartments within the same storage unit to be set and maintain different temperatures. In addition to optimized performance, thermoelectric cooler assemblies help address new regulations restricting the use of certain refrigeration liquids. These regulations will be implemented in the next 3 to 5 years depending on country. Economically-friendly thermoelectric cooler assemblies do not use refrigerants and thereby can be an alternative to compressor-based cooling systems.

Food Standards

According to the U.S. Department of Health and Human Services, foodborne diseases cause approximately 48 million illnesses, 128,000 hospitalizations, and 3,000 deaths in the United States each year. While technological advances such as pasteurization and proper canning have all but eliminated some diseases, new causes of foodborne illness have been identified. Epidemiological outbreak data repeatedly identify five major risk factors related to employee behaviors and preparation practices in retail and food service establishments as contributing to foodborne illness:

- Improper holding temperatures

- Inadequate cooking such as undercooking raw shell eggs

- Contaminated equipment

- Food from unsafe sources

- Poor personal hygiene

Refrigeration of food and beverage slows bacterial growth. Moisture, favorable temperatures and fuel (food/beverage) are the three ingredients that allow harmful bacteria to grow. Bacteria grow most rapidly in the range of temperatures between 5˚C and 57˚C. This dangerous temperature zone enables the number of bacteria to double in as little as 20 minutes. A refrigerator set at 5˚C or below will protect most foods and beverages. For safety, it is important to verify the temperature of any refrigerator system.

As a result, several food codes from the National Sanitation Foundation (NSF) address these concerns for manufacturers of food and beverage equipment. NSF standards and certification serve as the benchmark by which all commercial foodservice equipment products are measured.

- NSF/ANSI 4: Commercial Cooking, Rethermalization and Powered Hot Food Holding and Transport Equipment: NSF/ANSI 4 establishes minimum food protection and sanitation requirements for the materials, design, construction and performance of commercial cooking, rethermalization and hot food holding and transport equipment and their related components. This includes ranges, ovens, fat/oil fryers, fat/oil filters, griddles, broilers, steam and pressure cookers, kettles, toasters, rotisseries, hot beverage makers and component water heating equipment, proofing boxes and cabinets, hot food holding and transport cabinets, rethermalization equipment, etc.

- NSF/ANSI 7: Commercial Refrigerators and Freezers: NSF/ANSI 7 establishes minimum food protection and sanitation requirements for the materials, design, manufacture, construction and performance of commercial refrigerators and freezers and their related components. This includes storage refrigerators and freezers (reach-in, under counter, walk-in, roll-in); rapid pull-down refrigerators and freezers; refrigerated food transport cabinets, buffet units and food preparation units; display refrigerators; beverage coolers; and ice cream cabinets.

- NSF/ANSI 18: Manual Food and Beverage Dispensing Equipment: NSF/ANSI 18 establishes minimum food protection and sanitation requirements for the materials, design, construction and performance of equipment and devices that manually dispense food or beverages, in bulk or in portions, and their related components.

- NSF/ANSI 25: Vending Machines for Food and Beverages: NSF/ANSI 25 establishes minimum food protection and sanitation requirements for the materials, design, construction and performance of vending machines for food and beverages (including packaged and bulk foods) and their related components.

Thermal Management Techniques

To dissipate heat in beverage applications, manufacturers normally use active cooling technologies. Active cooling systems utilize compressor based or solid-state heat pump (thermoelectrics) to enhance the heat transfer process.

A conventional compressor based system contains three fundamental parts: the evaporator, the compressor, and the condenser. The evaporator (cold section) is where the pressurized refrigerant passes through the expansion valve and expands, boils, and evaporates. During this change of state from liquid to gas, energy (heat) is absorbed. The compressor acts as the refrigerant pump and recompresses the gas into liquid. The condenser expels both the heat absorbed at the evaporator and the heat produced during compression into the ambient environment.

A thermoelectric cooler is comprised of both p- and n- type materials brought in contact to form a junction. When the device is connected to a battery or other power source, electrons will flow. At the cold junction, energy (heat) is absorbed by electrons and moves from a low-energy state in the p-type semiconductor element, to a higher energy state in the n-type semiconductor element. The battery provides the energy to move the electrons through the system. At the hot junction, energy is expelled to a heat exchanger as electrons move from a high-energy level to a lower energy level. Reversing the direction of current flow reverses the heat pumping direction. This allows the thermoelectric device to provide both cooling and heating with a simple reversal of the current. Thermoelectric coolers are solid-state devices having no moving parts, fluids or gasses. The basic laws of thermodynamics apply to these devices just as they do to conventional heat pumps, absorption refrigerators, and other devices involving the transfer of heat energy.

Advantages and Disadvantages of Compressors and Thermoelectrics

Compressor-based and thermoelectric-based cooling solutions each have advantages and dissadvantages in beverage cooling applications. For example, compressor-based coolers can get colder much faster than thermoelectric coolers. This is why they are currently the preferred solution in freezer applications. However, thermoelectric cooler assemblies can cool to well below 0˚C depending on time contraints.

The food and beverage market has historically been hesitant to select a thermoelectric-based system due to preconceptions about higher cost, energy efficiency or lack of experience with thermoelectrics. Previously, thermoelectric-based cooling systems were more expensive than compressor solutions. However, in recent years, the decreasing cost of thermoelectric cooling solutions, and the increasing cost on compressors and refrigerants that follow regulations, makes these a viable alternative. When long-term maintenance and repair costs are factored in, thermoelectric cooling solutions can be a more cost-effective cooling solution. A thermoelectric cooler assembly can replace the need for a compressor, motor and refrigerants. High-efficiency fans can be added to a thermoelectric cooler assembly solution, which are the only moving parts for circulation of air and heat dissipation in the cabinet. While these fans are rated for up to 70,000 hours, they can also be controlled at lower speeds to extend life. They are also designed to be a part of the system that can be easily exchanged in the field. The compressor-based system relies on moving parts and coolants for operation. Both the compressor and motor are required to move the working fluid through the system, while fans are used to circulate the air through the evaporator. A compressor system’s components will wear out over time due to friction, thermal expansion, and on-off control. Friction wear is a constant problem in this system and exacerbated by temperature fluctuations in the environment and control side. Additionally, leakage of the refrigerant can occur through seals that fatigue from continuous operation. This loss of refrigerant will degrade system performance and impact the quality of the beverage being dispensed.

The energy efficiency of a thermoelectric cooler is dependent on ambient temperatures. The DC power thermoelectric coolers will pump heat at a rate proportional to the power applied. Therefore, when cooling needs are low, the thermoelectric cooler will consume less power to maintain control of the temperature. When additional cooling is required, the thermoelectric cooler will consume more power. For example, as the temperature difference between a wine cooler and room temperature increases, so does the amount of power needed to refrigerate the wine cooler. As a result, compressor units tend to operate more efficiently in hot weather. However, AC power compressor systems are either entirely “ON” or “OFF”. There is no proportional control, so full power must be applied at all times. Furthermore, the start-up current for a compressor system is often three times the steady state operating current and the circuit must be sized to handle it. Combining the non-proportionality, repeated ON-OFF control with the high-power draw at start-up and those efficiency gains at steady-state are reduced.

A thermoelectric cooling solution has no working refrigerants and can be shipped, handled, and mounted in most orientations without affecting its performance or reliability. A thermoelectric cooling solution can be top-, wall- or door-mounted in either vertical or horizontal direction. A compressor-based system cannot accommodate multiple mounting orientations, so a special unit is required for top mount, front mount installation. Thermoelectrics not only simplify the method of shipping and installation, but also offer an environmentally safe cooling solution. Compressor-based solutions depend on a chemical coolant to function as a heat sink and carry heat from one location to another. Refrigerants are hazardous and the waste must be disposed of properly - discarding an old refrigerator unit can lead to serious consequences for the local environment and human health if the refrigerant leaks into the soil or water supply. New legislations are limiting some of the most commonly used in the next coming years.

Application Examples

Coffee Dispenser

Large, pay per cup coffee machines utilize several techniques to brew or prepare coffee. Water can be filtered through crushed beans, a powder can be diluted with water, or syrup can be mixed with hot water. This third technique requires the syrup packaging to be kept cold before use. Customized direct-to-air thermoelectric assemblies based such as the AA060 or DA075 series have been used for this application for over 10 years.

In addition, many machines offer milk, half & half and other flavored creamers that must be continually chilled to a specific temperature. Thermoelectric cooling solutions are becoming more popular because of their smaller size and lower maintenance requirements compared to compressor-based systems. In addition, thermoelectric cooling solutions do not use harmful refrigerant chemicals and therefore do not require any field retrofits.

Beverage Dispensing

Beverage dispensers, like those that use soda syrup mixed with carbonated water, typically require a thermoelectric solution based on a smaller size and lower operating noise. In addition, these applications require heat-pumping capacities of less than a couple hundred watts, thus a larger and louder compressor-based solution would not be appropriate for this low heat exchange application.

Wine Cooling

Wine is best served and consumed at a specific temperature. Reds are usually served at 62-68 degrees F, while whites are served colder at between 49-55 degrees F. Finer restaurants, hotels and other establishments prefer to offer wines at their specific optimum serving temperature. Today, sophisticated wine coolers can cool each bottle to an independent temperature. Highly efficient thermoelectric coolers offer precise thermal control with low noise and vibration operation to ensure wine is stored and served at the appropriate temperature.

Water Purifier Systems

Water purification systems reduce particles, contaminants, or imbalances in drinking water, making it safe for everyday consumption. Thermoelectric coolers are used in small water purification systems for optimal thermal management by both cooling and heating water.

Thermoelectric Assembly Solution

Laird Thermal Systems provides compact, solid-state thermoelectric cooling solutions for a wide range of beverage cooling applications. Compared to standard compressor based solutions, the 12V or 24V DC thermoelectric coolers and thermoelectric cooler assemblies offer superior reliability, design flexibility via vertical integration capabilities, and an overall lower cost of ownership. Thermoelectric coolers operate at lower noise levels and provide a more environmentally friendly solution. When combined with its advanced temperature controllers, Laird Thermal Systems’ space-saving thermoelectric cooler assemblies offer precise temperature control and stability. Laird Thermal Systems’ long history of providing custom thermoelectric cooler assemblies to the food and beverage industry includes expertise in engineering design services and a global presence that supports onsite concept generation, thermal modeling, mechanical and electrical design and rapid prototyping to deliver optimized thermal management for the food & beverage sector.