Introduction

Air conditioners utilizing thermoelectric coolers are often considered as an alternative to conventional vapor-compression systems for enclosure cooling. Because a thermoelectric cooler is compact, robust, and completely solid-state, the inherent reliability of such a system is attractive to engineers and end-users alike. However, there is an inherent reluctance to choose a thermoelectric-based system due to preconceptions about energy efficiency or lack of experience with thermoelectrics.

Here we compare and contrast two cooling technologies. Comparisons of efficiency, reliability, control, as well as installation and maintenance, demonstrate that a thermoelectric based solution can have significant advantages over conventional compressor based systems.

Technology Comparison – How it Works

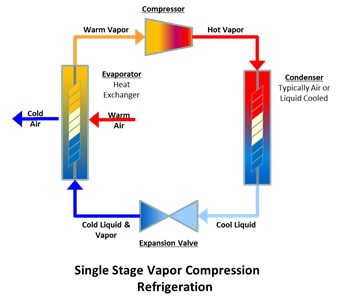

A conventional compressor based system (shown above) contains three fundamental parts: 1) the evaporator, 2) the compressor; 3) the condenser. The evaporator (cold section) is where the pressurized refrigerant passes through the expansion valve and expands, boils, and evaporates. During this change of state from liquid to gas, energy (heat) is absorbed. The compressor acts as the refrigerant pump and recompresses the gas into a liquid. The condenser expels both the heat absorbed at the evaporator and the heat produced during compression into the ambient environment.

A thermoelectric-based system is comprised of both p- and n- type materials brought in contact to form a junction. When the device in connected to a battery or other power source electrons will flow. At the cold junction, energy (heat) is absorbed by electrons and moves from a low-energy state in the p-type semiconductor element, to a higher energy state in the n-type semiconductor element. The battery provides the energy to move the electrons through the system. At the hot junction, energy is expelled to a heat exchanger as electrons move from a high-energy level to a lower energy level. Reversing the direction of current flow reverses the heat pumping direction. This allows the thermoelectric device to provide both cooling and heating with a simple reversal of the current.

Thermoelectric coolers are solid-state devices having no moving parts, fluids or gasses. The basic laws of thermodynamics apply to these devices just as they do to conventional heat pumps, absorption refrigerators, and other devices involving the transfer of heat energy.

Power

Thermoelectrics operate on DC power. These can be configured to run on a variety of DC voltages by selecting a series or parallel configuration of the internal construction of a thermoelectric cooler. The most common voltages are 24 and 48 VDC. Since they require DC, a power supply is often used to convert AC to DC.

DC operation offers several advantages over AC. Thermoelectric coolers will pump heat at a rate proportional to the power applied. Therefore, when cooling needs are low, the thermoelectric cooler will consume less power to maintain control of the temperature. When additional cooling is required, the thermoelectric cooler will consume more power. This control allows for efficient use of power, while reducing the power cycling inherent in on-off type controllers. Furthermore, since thermoelectric coolers can heat or cool dependent upon the direction of current flow, they eliminate overshooting of the set point temperature and more precise temperature control can be achieved.

Various line power levels in geographic regions require AC compressors and fans to run on specific voltages and frequencies. This increases the number of components required to support each region and makes the unit susceptible to the possibility of brown-outs. Power supplies, however, can operate on a universal range of input voltages and frequencies. This enables the cooling system to run efficiently in geographic areas that have limited reliable output power and can maintain operation of a thermoelectric cooler during a brown-out (low voltage condition).

In heating mode, a thermoelectric system requires less power consumption than a compressor-based system. Enabling heating or cooling with the same thermoelectric device, the thermoelectric cooler requires fewer parts and prevents rapid cycling from thermal overshooting of competing cooling and heating components. This is accomplished by reversing the direction of current to the thermoelectric cooler. The net result is a high degree of control, energy efficiency, and reliability. A compressor system usually incorporates a separate heating component because compressors cannot be powered in reverse.

Conventional compressor-based air conditioners are typically AC powered. Today’s compressors are more efficient than a decade ago. In steady-state operation at maximum designed heat loads, they can be the most energy efficient choice. Under this condition, a well-designed compressor based system will use 30% to 35% less power than the equivalent thermoelectric system.

Many enclosure applications, especially those in remote or outdoor environments, have environmental conditions that fluctuate throughout the day and over the course of a season. Compressor systems are either entirely “ON” or “OFF”. There is no proportional control, so full power must be applied at all times. Furthermore, the start-up current for a compressor system is often three times the steady state operating current and the circuit must be sized to handle it. Combining the non-proportionality, repeated ON-OFF control with the high-power draw at start-up and those efficiency gains at steady-state are reduced.

Reliability

Thermal management of an enclosure is necessary to extend the reliability and maintain optimal performance of electronics. Therefore, it is critical that the most reliable climate controlled technology be applied.

A thermoelectric cooler is a solid-state device. There is no compressor, motor or refrigerants involved. The only moving parts are the hot side and cold side fans for circulation of heat absorption in the cabinet and heat dissipation to environment. While these fans are rated for up to 70,000 hours, they can also be controlled at lower speeds to extend life.

Thermoelectric coolers with a Proportional Integral Derivative (PID) controller, can achieve more than 70,000 hours of operation. With an integrated PID controller, the thermoelectric cooler does not suffer from stresses induced by the stop-start power surges or temperature overshoot variations. Therefore, the higher reliability of steady-state conditions are maintained.

The compressor based system relies on moving parts and coolants for operation. Both the compressor and motor are required to move the working fluid through the system, while fans are used to circulate the air through the evaporator. A compressor system’s components will wear out over time due to friction, thermal expansion, and on-off control. Friction wear is a constant problem in this system and exacerbated by temperature fluctuations in the environment and control side. Additionally, leakage of the refrigerant can occur through seals that fatigue from continuous operation. This loss of refrigerant will degrade performance and stop protecting critical electronics.

Handling and Installation

A thermoelectric cooler assembly has no working refrigerants and can be shipped, handled, and mounted in any orientation without affecting its performance or reliability. This not only simplifies the method of shipping, but offers options to orient the unit to maximize circulation. A single thermoelectric cooler assembly design can be top-, wall- or door-mounted in either vertical or horizontal direction and one model can satisfy multiple orientation installation choices. Gravity will only affect the orientation if the application reaches dew point because condensation routing methods will be gravity-dependent and must be considered in the design.

A thermoelectric cooler assembly is smaller, requiring less surface area for mounting and overall volume, than a compressor-based system when capacities are less than 500W (1700 BTU). Typical size and weight savings can range from 25% to 50%.

Because of the refrigerant, a compressor-based system must be kept in a specific orientation during shipping, handling, and installation or damage to the system may occur. Compressors also tend to be heavier and are larger than comparable thermoelectric based systems. This requires mounting surfaces and possibly multiple technicians needed for installation. A compressor-based system cannot accommodate multiple mounting orientations, so a special unit is required for top mount, front mount installation. This requires more models to carry in inventory.

Vibration

Vibration has a cumulative effect of loosening hardware connection of the cooling unit, as well as the electronics within the enclosure. The thermoelectric cooler assembly operates silently with minimal to no vibration. The only vibration comes from the DC fans, which are vibration damped with rubberized fasteners. The thermoelectric cooler assemblies do not contribute to loose hardware or other vibration issues that can occur from long term operation. A compressor-based system has several moving parts, which cycle and vibrate constantly when powered on. This contributes to an overall higher noise level and vibration, which can be detrimental to the system level electronics housed within the enclosure.

Temperature Control

The temperature control specification for an electronics enclosure is typically +/- 2°C or greater. This allows hysteresis to be designed in, reducing cycling between cooling and heating or on/off when the enclosure is at its set point temperature. This range is suitable for thermostatic control, but a tighter tolerance requires a proportional type of control.

A thermoelectric based controller can drive the temperature of an enclosure to within 0.5°C of the set point temperature. This is accomplished with the integrated bi-directional PID control, adjusting the net power to the thermoelectric cooler allowing fine tuning and rapid response to component or environmentally-induced heat load fluctuations. The operating range for a typically thermoelectric cooler is -40°C to +65°C for most systems.

Compressor-based systems are typically designed for operation between 20°C and 55°C. This range is useful for most enclosure applications and operating environments. If heating is required, a separate heater and switching circuit must be used or if higher or lower temperatures are desired, a special compressor for that range (refrigerant, hardware) must be designed.

Air Conditioners: Thermoelectric vs. Compressor-based

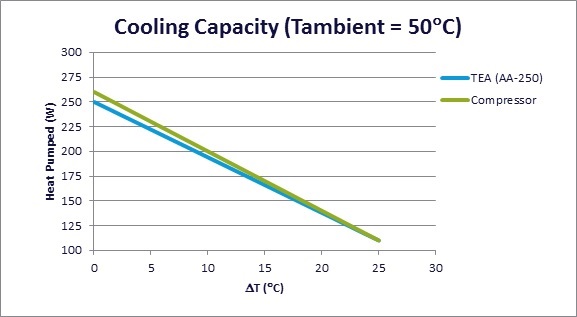

The graph below compares the cooling capacity of a thermoelectric cooler assembly to a compressor based air conditioner from a manufacturer’s datasheet. The initial interpretation is that the compressor appears to have more cooling power than a thermoelectric cooler assembly (260W v. 250W) under a DT= 0°C in an ambient of ~ 50°C. However, in actual application conditions (DT= 20°C), the two units’ cooling capacities are similar (140W v 138W).

Typical Enclosure Application for Telecom Battery Back-Up System

For reliability and maximizing useful life, the batteries require temperature control from an ambient environment that can fluctuate above and below battery temperature limits.

Cooling/Heating Conditions

Ambient Temperature: -33 to +50°C (average +35°C)

Control Temperature: +10 to +30°C

Heat leak rate through cabinet walls: 5W/°C

Active Internal heat load: 20 Watts

Model Comparison

AA-250-48-44-00-XX

Ratings:

Useful Cooling @ L35, L35 (internal, external temperature, °C) = 244W

Useful Cooling @ L35, L50 (internal, external temperature, °C) = 166W

Rated Voltage: 48 to 56VDC

Power Usage @ L35, L35 (internal, external temperature, °C) = 290W

Power Usage @ L35, L50 (internal, external temperature, °C) = 259W

Dimensions W x H x D: 153 x 400 x 204 mm

Weight: 6.3 kg

Leading Compressor-based Air Conditioner

Ratings:

Useful Cooling @ L 35, L 35 (internal, external temperature, °C) = 300W

Useful Cooling @ L 35, L 50 (internal, external temperature, °C) = 150W

Rated Voltage: 115VAC, 60Hz

Power Usage @ L 35, L 35 (internal, external temperature, °C) = 290W

Power Usage @ L 35, L 50 (internal, external temperature, °C) = 340W

Dimensions: W x H x D: 525 x 340 x 135 mm

Weight: 17 kg

Overview

In this application, a bank of batteries within a cabinet requires temperature control to extend the life, so they can be used during emergency power outages. The ambient temperature can range from a high of +50°C to a low of -33°C. The enclosure must be kept between +10°C and +30°C during these environmental conditions for battery protection.

This comparison demonstrates the performance and efficiency of the best matched, commercially available thermoelectric and compressor-based models. The data used in this study comes from both manufacturers’ data sheets and modeling software; power usage was confirmed with manufacturers’ representatives. The rate of heat leaking into and out of the cabinet is determined by the surface area and insulation value. In this comparison, the heat leak rate was 5W/°C.

For example, a 20°C temperature difference between the ambient and internal temperature results in a 100W heat loss/gain (20°C x 5W/°C = 100W). The cooling and heating solution must offset these losses or gains.

Cooling Mode: Demonstrates the power usage required to maintain the enclosure temperature to specification (+30°).

Heating Mode: Demonstrates the power usage required to maintain the enclosure temperature to specification (+10°C). Data compensates for the 20W active load within the cabinet.

Special Notes

- To insure accuracy, this comparison makes the following considerations:

- The DC-powered thermoelectric cooler assembly is shown with both 100% and 90% efficient DC power supplied. The 90% efficient data demonstrates the power usage if DC power is not organic to the enclosure and a commercial-grade AC/DC supply is required.

- The compressor draws only 3.3A, even though the specification sheet shows 4A. The manufacturer suggests that the lower current value is more accurate.

- Start-up current was not considered due to transience and short duration. The start-up current for the thermoelectric cooler assembly is ~25% greater than steady-state; start-up current for the compressor is ~300% greater than steady-state.

- The compressor unit does not have a heating function and uses an auxiliary resistive heater. This was not included in the dimension or weight values.

- The thermoelectric cooler assembly may require a separate DC power source if not organic to the enclosure. This was not included in the dimension or weight values.

- Thermoelectric cooler assembly power usage includes inside and outside fan power.

- Thermoelectric cooler assembly power usage is shown with both proportional and duty cycle (on/off) control.

- Compressor power usage is based on duty cycle (on/off).

Results

The tables and graphs in the pdf version of this paper provide the measured efficiencies under a range of environmental temperatures.

Cooling Mode

The thermoelectric cooler assembly is up to two times more efficient than the compressor-based unit with proportional control in all test conditions. When the thermoelectric cooler assembly is cycled on/off, the compressor has advantages where the temperature difference and heat load is smaller. Overall, the thermoelectric based unit requires less power to maintain the specified set point temperature than a compressor based unit.

Heating Mode

The thermoelectric cooler assembly is up to 20 times more efficient across test condition ranges. This is because both the input power to the thermoelectric cooler assembly, plus the heat pumped by the thermoelectric cooler assembly is provided as heat. The efficiencies are most notable when the temperature differential (DT) is lower.

Summary

| Thermoelectric Based | Compressor Based | Comments | |

| Power Usage | Best with proportional control in cooling mode and heating mode | No proportional control; affects overall efficiency | Thermoelectric cooler assembly is more efficient over wider range of temperatures |

| Reliability | > 70,000 hours | Unpublished | Fan is only moving part in thermoelectric cooler assembly |

| Power Input | DC required | AC required | DC more flexible to accommodate multiple geographic regions |

| Reliability | Solid-state heat pumping; proportional control; fan is only moving part | Mechanical pump, refrigerants, fans. On-off switching duty cycle | Fan is only moving part in thermoelectric cooler assembly |

| Handling and Installation | Can be shipped, stored, and installed in any orientation (top, vertical, horizontal) | Refrigerant (R134a) requires unique orientation | Condensation control may dictate some design-orientation in thermoelectric cooler assembly |

| Noise / Vibration | < 61 dB(A)/ none | < 61 dB(A) / mechanical | Fan is only moving part in thermoelectric cooler assembly with option to speed control |

| Maintenance | No disassembly needed. Periodic compressed air over heat sinks | Disassembly required to access coils and chambers. Compressed air, replenishment of refrigerant | Thermoelectric cooler assembly has low total cost of ownership |

| Temperature Control | <0.5°C | ≥2°C | TE controller accuracy to < 0.5°C, if required, using PID |

| Size | 0.0127m3 | 0.0273m3 | Thermoelectric cooler assembly takes up less volume than compressor based system |

| Weight | 7kgs | 17kgs | Thermoelectric cooler assembly weighs less than compressor based system |

Conclusion

A thermoelectric cooler assembly has considerable advantages over a comparably-sized, compressor-based solution in climate-controlled electronic enclosures. It can both cool and heat, offering more precise temperature control than a compressor-based unit and is more energy efficient throughout the temperature range of the application, by 25% to over 90% in cooling mode and up to 400% in heating mode.

The thermoelectric cooler assemblies solid-state construction provides advantages in reliability, installation, vibration, and low cost of maintenance. Additionally, its compact form factor and lighter weight allows for easier installation and occupies less space than a compressor-based unit. The unit operates on DC power. This makes it much easier to utilize globally regardless of the available AC line voltage and frequency.

Utilizing a thermoelectric cooler assembly in climate-controlled electronic enclosures provides an attractive alternative solution because of its efficiency, reliability, accuracy, compact design, negligible noise levels, and ease of installation.