Introduction

At Laird Thermal Systems, we are committed to eco-friendly solutions for temperature stabilization for demanding applications across global medical, analytical, industrial, transportation, and telecommunications markets.

Older compressor-based systems often use high global-warming potential (GWP) HFC refrigerants like R134a and R404A. New industry requirements are moving away from the use of such refrigerants due to their environmental impact. New government restrictions on traditional and natural refrigerants are central to compressor-based systems.

Modern compressor-based systems now use a variety of natural refrigerants, as they have little to no Ozone Depletion Potential (ODP) and GWP, making them the more sustainable choice: R744 (carbon dioxide), R717 (ammonia), R290 (propane), R600a (isobutene), and R1270 (propylene). However, natural refrigerants pose different design challenges such as increased pressure, high toxicity, flammability, asphyxiation, and relatively poorer performance. The flammable nature of some natural refrigerants makes them hazardous to transport. As a result, some OEMs are looking for alternative technologies such as Peltier cooling.

Refrigerant-Free Thermoelectric Coolers

Refrigerant-free thermoelectric coolers and thermoelectric cooler assemblies deliver an eco-friendlier solution that accommodates long-term life cycles for electronics and various lab and tech instruments.

Our thermoelectric assemblies, such as SuperCool Series, provide a refrigerant-free alternative to compressor-based systems, making it environmentally friendly and compliant with strict regulations banning hazardous refrigerants that deplete the ozone layer. Our Peltier cooling assemblies utilize thermoelectric coolers to offer a higher cooling capacity spectrum, ranging from approximately 10 to 250 Watts.

However, not all Peltier cooling solutions are suitable for every application, and refrigerated liquid cooling systems offer unique advantages that cannot be easily replaced. It's essential to understand that Peltier cooling solutions have limitations in terms of their cooling capacity and efficiency. They may not be suitable for high-performance machines or devices that require significant cooling power. Peltier cooling systems are generally more suitable for low-power applications or small-scale cooling needs. For example, they are most beneficial in applications with tight space constraints, lower heat load capacities (typically less than < 400W) or requiring cooling of a specific sensitive electronic below worst-case ambient such as LiDAR or CMOS, temperature need for precise temperature control, such as in medical equipment or optoelectronics among others. On the other hand, refrigerated liquid cooling systems offer several advantages. They are highly efficient in dissipating heat and can handle high-performance cooling requirements, making them ideal for equipment that generates a substantial amount of heat.

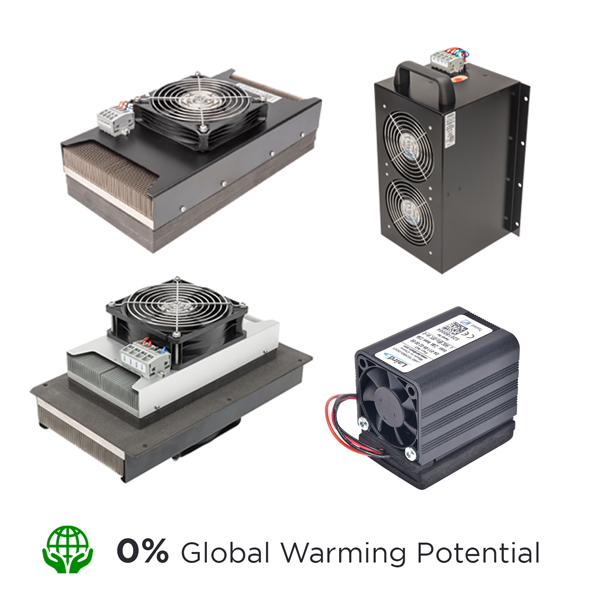

Eco-Friendly Refrigerated Liquid Cooling Systems (Chillers)

Furthermore, it's important to consider governmental restrictions and regulations related to cooling systems. Many governments around the world are focusing on environmental protection and sustainability, which includes restrictions on the use of certain refrigerants that are harmful to the environment, such as hydrofluorocarbons (HFCs). Chillers can be designed with eco-friendly refrigerants that comply with these regulations, making them a more environmentally responsible choice.

Our Nextreme™ Performance Series recirculating chillers platform features high-quality components, environmentally friendly refrigerants, low-noise components and a user-friendly operator interface at a standard price. The new chiller utilizes high-performance variable speed motors for noise reduction, lower room heat input and reduced energy consumption by up to 50% compared to conventional compressor-based systems. By using a more environmentally friendly R513A refrigerant, it delivers similar performance with less than half the Global Warming Potential (GWP) compared to traditional hydrofluorocarbons (HFC) refrigerants.

An Even Greener Alternatives

The NRC400 benchtop recirculating chiller is a unique product from the Nextreme Series as it is a thermoelectric chiller that doesn’t use any refrigerants. It combines advanced thermoelectric cooling technology with high-performance heat exchangers to deliver 400 watts of cooling power while achieving temperature stability of ±0.05°C. Because thermoelectric chillers do not use any refrigerants, the NRC400 is an environmentally friendly cooling solution providing zero global warming potential. It is also approved by UL for laboratory use, has CE marking and is RoHS compliant.

Alternative refrigerants are considered the future option for refrigerated liquid cooling systems due to their low environmental impact. Today, most refrigerants have an Ozone Depleting Potential (ODP) of 0 and a Global Warming Potential (GWP) ranging from ~500 to ~4000. Refrigeration systems using R-290 has an ODP of 0 and GWP of only 3.

Thus, Laird Thermal Systems has launched the Alternative Refrigerant-Based Cooling Systems Initiative to address concerns about climate change and new industry regulations. When using the environmentally friendly R-290 propane refrigerant, liquid cooling systems can deliver maximum performance and cooling capacity with a low impact on global warming. Alternative-refrigerant technology will be introduced in our upcoming product platforms.

Inquire about our upcoming Nextreme Eco-Friendly Solution for your application.

Also, you can use our Thermal Wizard to find the best thermal solution based on your requirements.

Related Products

Stay tuned for updates on thermal management industry regulations, new product releases, and innovative temperature control approaches with

LTS Thermal Solutions Spotlight:

Categories

Blog Date