In order to bring the temperature down of an object or chamber, heat must be removed faster than it can be created. There are two primary attributes that the designer needs to determine to specify a TEA for their application.

The first parameter is calculating the cooling capacity requirement. This is achieved by estimating the total heat load of the system, Qt :

Q t = Qa + Qp + Qr

This consists of calculating the active heat load (Qa ), passive heat load (Qp ), and for outdoor applications, the radiant heat load (Qr ). The active heat load consists of the load from objects to be cooled, powered electronic devices, and the dehumidification of air. The heat from active devices can simply be measured by the input power to a device. When the object being cooled is at a lower temperature than the ambient environment, heat from the ambient environment will naturally be drawn to the cold source in order to reach equilibrium in the surrounding environment. This is known as passive heat load. It is critical to minimize this parameter as thermal shorts in system level design, will require TEAs to pump more thermal energy in order to keep source control temperature. As a result, the TEA will be less efficient. Therefore, insulating the chamber walls or objects to be cooled as much as geometric constraints will allow is required to maximize the efficiency of the TEA. For outdoor applications, the radiant (solar) heat load must also be considered, which is infrared heat generated from the sun. Solar shields are commonly used to reduce the effects of solar heat load.

Performance Curve

The second primary parameter is defining the temperature differential:

ΔT = Ta - Tc

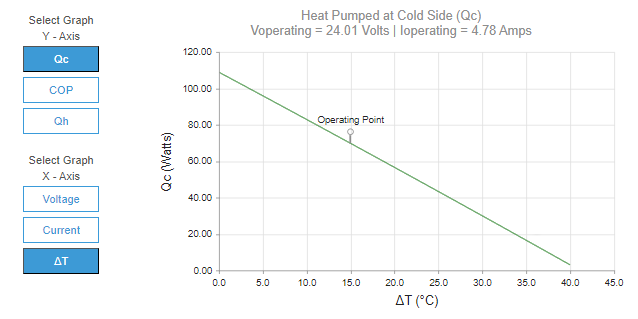

This is defined as the difference between the temperature in the ambient environment (Ta) and the desired control temperature of the application (Tc). Ta is generally chosen to be the worst case ambient that the application will be exposed to. As the temperature differential increases, more thermal energy is required to achieve a colder control temperature so the cooling capacity (Qc) will go down. Reference the performance chart on the right as an example. This is the performance curve of an AA-060 assembly that measures the heat pumping capacity of the TEA against temperature differential. The performance curve is based on an ambient temperature of 32˚C. The cooling capacity of an AA-060 at ΔT = 5˚C is 50 Watts and lowers to 30 Watts at a ΔT = 20˚C. Once the total heat load and temperature differential have been defined, the designer can now specify a TEA to meet the cooling parameters of an application by referencing the performance charts of each unit. Since Qt is a difficult parameter to calculate due to the necessity to characterize all heat loads and losses, Laird Thermal Systems recommends incorporating a 20% safety factor into the Qt value. The benefit of this is that there is extra cooling capacity which accelerates the cool down cycle, and with closed loop feedback control, the TEA can run at a percentage of maximum power input to minimize efficiency losses.

Related Products

Stay tuned for updates on thermal management industry regulations, new product releases, and innovative temperature control approaches with

LTS Thermal Solutions Spotlight: