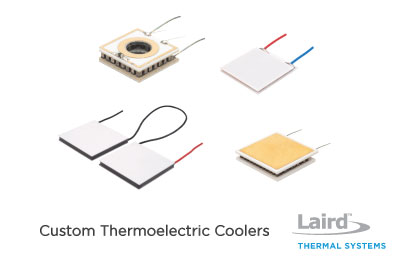

Standard thermoelectric coolers in our product catalog may not always meet your application requirements. Our wide range of form factors, sealing and finishing options offer additional configurable flexibility that can provide optimized fit to your application. All thermoelectric coolers are made with high-grade ceramics and semiconductor materials, resulting in Best-in-Class quality performance products. The options we provide include different form factors, finishes, thickness tolerance, ceramic substrates, sealants and wire lengths. Minimum order quantities apply.

View our Thermoelectric Cooler Options brochure for a complete list of available options.

How to Begin your Project

If you are looking for a custom thermoelectric cooler, fill out the Request a Quote form and our project team will respond to you. You will be asked to send us your specifications using the Custom Prototype Requirements form. These specifications, including cooling capacity, size constraints, and available input voltage, are taken into consideration when designing a custom thermoelectric cooler. It will also serve as the basis for quotation purposes and as a checklist throughout the process to ensure all requirements are met.

What to Expect

- Based on your requirements, Laird Thermal Systems’ project team will develop the optimum thermoelectric solution for your application. During this stage, we will provide expected performance characteristics based on calculations validated by measured test data.

- When the design is approved, the thermoelectric cooler prototype is built in our ISO 9001:2015 certified manufacturing and design center in Shenzhen, China.

- Customers are asked to review the prototype and determine if any modifications are required.

- In the final stage, we verify that the custom thermoelectric cooler passes all critical tests performed in the intended application. For some applications, mechanical and environmental testing is required. For example, PCR applications require thermal cycle testing to verify the required number of thermal cycles the thermoelectric cooler can undergo without impacting performance. Applications in the telecom industry may require tests to verify the cooler meets Telcordia Standards.

If you have any questions, please contact our thermal experts at Laird Thermal Systems.