Introduction

The trend to miniaturize medical diagnostic and analytical instrumentation to free up precious lab space has led engineers to pack more functionality into a tighter space constraint. This increases the heat flux by packing electronics in a smaller footprint and has led to thermal challenges. Waste heat must be efficiently managed to meet conflicting requirements of increased performance with reduced power consumption and quieter operation all in a compact design. For systems that require refrigeration for specific reaction temperatures, such as benchtop incubators, laboratory centrifuges, chromatography and clinical chemistry analyzers, temperature control systems play an important role in performance, size and improving test results. One popular cooling solution that enables OEMs to meet these thermal challenges utilizes thermoelectric cooler assemblies with integrated temperature control.

Thermal Management Techniques

Manufacturers utilize a wide range of thermal management solutions that predominantly fall into two categories: active and passive cooling. Active cooling systems utilize compressor based or solid-state heat pumps (thermoelectrics) to cool below ambient temperatures. Passive thermal management solutions solely rely on heat transfer by conduction, or convection to transfer heat and are typically comprised of interface materials and heat sinks and fans. Passive technologies are most commonly used where cooling to ambient is sufficient.

Application Examples

Automated blood analyzers and centrifuges are used in healthcare, forensic and bioscience labs. This equipment requires colder temperatures to extend life of reagents. Formerly, these machines utilized compressor based systems or recirculating chillers to enable this type of thermal control. Today, many modern systems are turning to thermoelectric based systems to improve overall system performance in a tight space constraint.

Immunoassay and clinical chemistry analyzers are instruments used in the clinical laboratories of hospitals and centralized labs for diagnosing diseases, monitoring diseases, and drug testing. Commercial systems today can test for hundreds of different parameters in patient fluid samples. These analyzers use chemical reactions to quantify substances such as glucose, cholesterol, proteins and enzymes in patient fluid samples. There are a number of different types of measurement technologies used, including photometry, colorimetry, potentiometry, and others. Immunoassay analyzers are also used to detect and quantify chemical substances in patient samples. These systems, however, are specifically designed to measure the concentration of a substance using the reaction of an antibody to its antigen. There are standalone clinical chemistry and immunoassay analyzers, as well as integrated systems that perform both kinds of tests. Automated systems range in size from smaller systems that hold a limited number of reagent samples and run a limited number of tests to larger systems that hold a large number of reagent samples and run a wide range of tests. Clinical chemistry and immunoassay analyzers require reaction reagents. Reagents are often stored onboard the system, and the reagent chamber is sometimes cooled to increase reagent shelf life. Cooled reagent chambers are typically held at a constant temperature, typically between 4°C to 8°C. Thermoelectric cooler assemblies can be used to cool the reagent chamber as an alternative to conventional compressor-based systems.

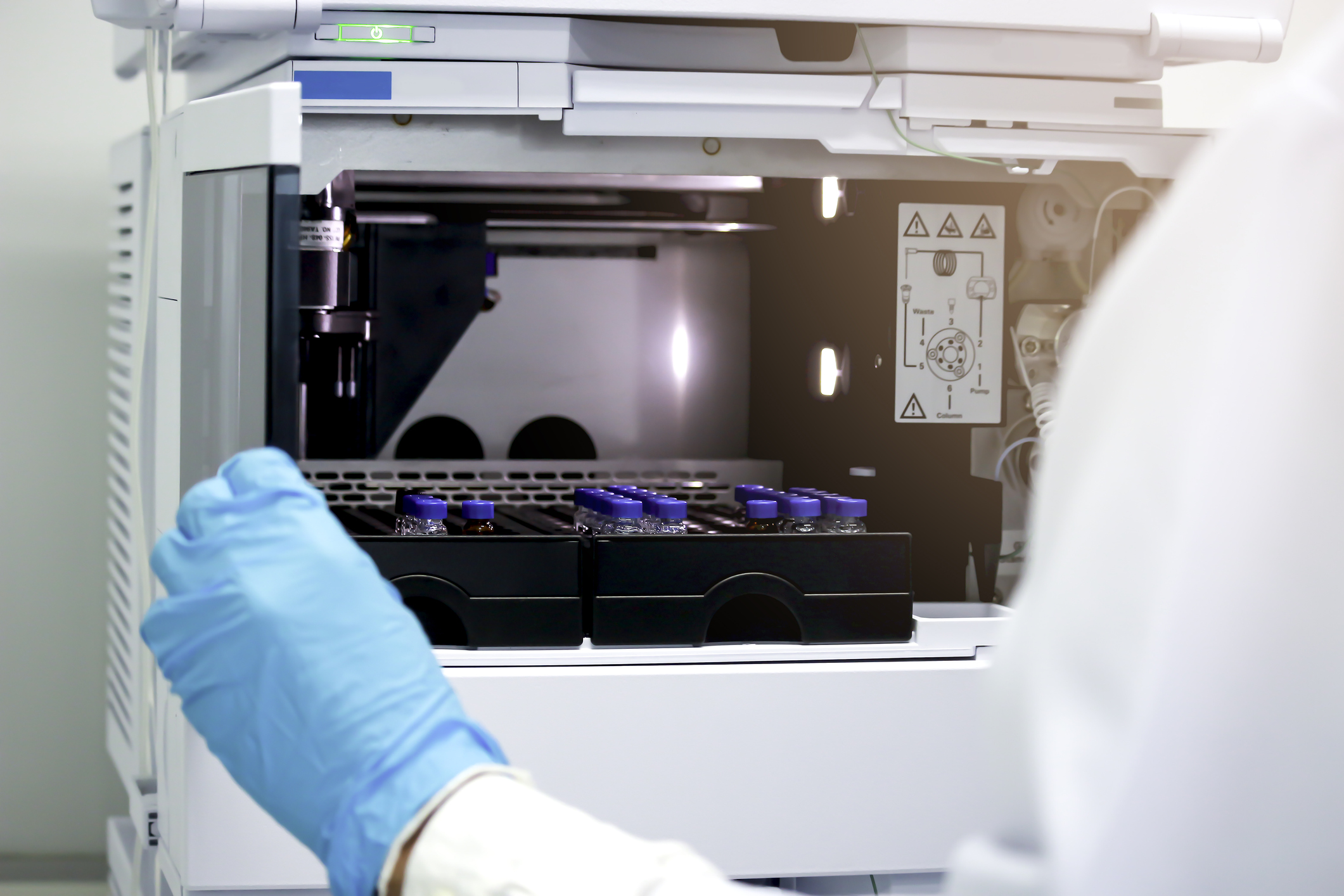

Liquid chromatography is a technique used for analysis of mixtures by separating, identifying, and quantifying their constituent components. Liquid chromatography normally operates with smaller amounts of fluids and seeks to measure the relative proportions of analytes in a mixture. R&D laboratories in the pharmaceutical, food science and oil & gas industries use these instruments for product development or reverse engineering. Temperature control plays a major role in the sample storage process while samples are waiting to be analyzed by the LC. There are two major uses of thermoelectrics in controlling the temperature of high-performance liquid chromatography (HPLC) instruments; temperature control of the sample storage compartment by thermoelectric cooling and heating, and the heating and cooling of the separation column. In modern HPLC equipment, thermal management systems are used to provide temperature stability and condensation protection. Depending on the mixture, precise temperature control ranging from 4 to 40 °C is required. Heat load requirements typically range from 20 to 100 Watts, with some newer machines requiring cooling up to 200 Watts to increase sample testing throughput. In addition, many new HPLC instruments feature multiple sample storage chambers that have different cooling/heating requirements, increasing the overall system heat load.

Thermoelectric Cooler Assembly Solution

Laird Thermal Systems has expanded its thermoelectric cooler assembly product offering with a series that includes a broad range of higher capacity systems in a small package. Previously, the Tunnel Series thermoelectric cooler assemblies offered cooling capacities up to 30+ Watts. The new boosted Tunnel Series offers cooling capacities in excess of 100 Watts to support larger chamber and storage compartments. Available in 12 and 24 Volt configurations, the boosted Tunnel Series offers a compact form factor that fits inside medical diagnostics and analytical instrumentation with tight geometric space constraints.

Laird Thermal Systems’ Tunnel Series feature air-to-air or direct-to-air heat transfer mechanisms designed to move air across heat sinks vs traditional impingement flow. This reduces the required airflow paths, which is important to accommodate tight space constraints. Thermoelectric coolers have been optimized for high efficiency and improved reliability. Additional design features include lower noise fans, improved sealing to prevent moisture intrusion and higher efficiency when compared to traditional thermoelectric cooler assemblies.

The space-saving Tunnel Series thermoelectric cooler assemblies offer compact cooling performance for analytical and medical instrumentation.

Precise Temperature Control

In addition, when combined with an advanced SR-54 Series temperature controller, the assembly offers temperature control to within +/- 1 °C. The SR-54 temperature controller also provides monitoring and alarm functionality, including identification of a problematic fan, over-temperature thermostat and temperature sensor failure — all of which are critical to maximizing medical equipment uptime. The controller requires minimal programming and can be easily adhered to a thermoelectric cooler assembly or system enclosure. The controller also lowers operational noise, as fan speeds can be reduced once the specified temperature has been reached.

Laird Thermal Systems’ SR-54 Series temperature controller

Conclusion

Cooling below ambient is vital in medical diagnostic and analytical instrumentation equipment like immunoassay and clinical chemistry analyzers. Operating temperature fluctuations in these machines can significantly affect the test results and shorten the life of reagents or samples. Laird Thermal Systems’ space-saving thermoelectric cooler assemblies provide temperature stability and condensation protection for analytical and medical instrumentation. The advantages of thermoelectric cooler assemblies over other cooling technologies are precise temperature control, compactness, faster temperature ramp rates, better efficiency, greater reliability and lower noise. Laird Thermal Systems’ new boosted Tunnel Series thermoelectric cooler assemblies meet the stringent temperature control requirements and mean time before failure demands of sensitive medical equipment.