Introduction

Modern microscopy equipment offers magnification, resolution, and contrast for visualization, measurement and analysis of microstructures to support imaging needs in life science and biotechnology research. Laboratory technicians have access to more sophisticated microscopy equipment than ever before providing high-quality images of cell structures. There are four types of microscopes; optical, electron, scanning probe microscopy, and the developing field of X-ray microscopy. Heat-sensitive electronics in all types of microscopy equipment require precise temperature control to ensure maximum image resolution and long-life operation. In this application note we will be focusing on optical microscopy.

Background

Optical microscopy technology involves visible light transmitted through or reflected from a sample. To enable a magnified view of the sample, light travels through one or multiple lenses in the microscope. The resulting image can be detected directly by the eye, imaged on a photographic plate, or captured digitally. Modern digital microscopes use a CCD (charge-coupled device) or CMOS (complementary metal-oxide semiconductor) sensor-based camera to project the sample image on a digital screen. The microscope may also contain several imaging sensors and field programmable gate array (FPGA) semiconductors to enhance image resolution.

Application Challenges

Imaging sensors in digital microscopes require precise temperature control at 18⁰C or lower to ensure maximum image quality, also during long exposures. CCD and CMOS image resolution significantly degrades as temperatures increase. Most of the heat in optical microscopes is generated by lasers used for scanning the sample. Waste heat in these smaller types of systems typically ranges from tens to hundreds of watts and a refrigeration system is most likely required for cooling below ambient temperatures.

Digital Microscopes require very precise temperature control to provide high-resolution images of microstructures.

Temperature Fluctuations

Sensitive camera optoelectronic components must be kept at a very precise temperature of ±0.5°C or better below room temperature. Precise temperature control is needed to keep the imaging sensor stable to maintain high image resolution. Cooling laser optics and other sensitive components is also key to reduce maintenance and maximize equipment uptime resulting in a lower total cost of ownership.

Noise & Vibration

A cooling system must also deliver a steady flow of coolant thru the liquid circuit with minimal pulsation. Vibrations from the pump flow can distort microscope imaging resolution, creating noise in the image. Large compressor-based systems are typically noisy and tend to vibrate. Thermoelectric-based chillers are designed with smaller fans and pumps providing lower noise and vibration in laboratory environments.

Environmental Regulations

Environmental regulations affect many markets and applications, and biotechnology research is no exception. Traditional compressor-based systems typically use harmful HFC refrigerants including R134a and R404A. Although modern compressor-based systems are significantly better for the environment by using natural refrigerants, they have their own complications, including flammability. Thermoelectric-based chillers do not use any refrigerants, resulting in zero global warming potential.

Thermoelectric Chiller Solutions

Because passive cooling solutions such as heat sinks and fans or ambient liquid cooling systems are unable to cool below ambient, thermoelectric-based recirculating chillers are a better solution. Providing a compact solution with few moving parts, thermoelectric chillers offer high reliability with minimal maintenance through the product life time. In addition, a recirculating chiller system that uses thermoelectric coolers offer more precise temperature control due to thermoelectric coolers’ ability to both heat and cool. The plug and play design provides quick and easy installation in any laboratory environment.

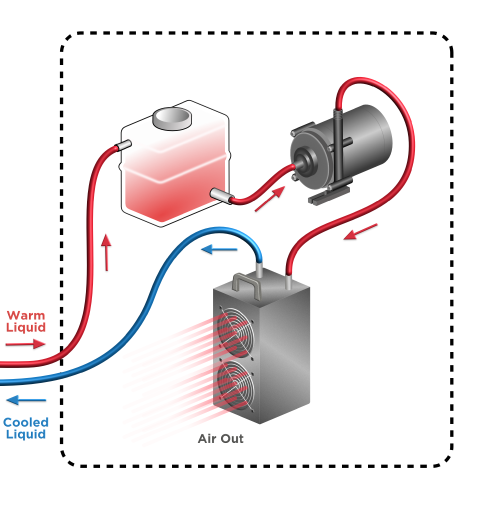

How Does It Work?

Heat generated by the microscope is absorbed by a liquid coolant that flows to a reservoir tank by using a pump. The pump pushes coolant through a Liquid-to-Air thermoelectric engine, which cools the coolant circuit while dissipating heat into the ambient environment. The coolant will then flow back to the camera system at the desired temperature setpoint.

Laird Thermal Systems Thermoelectric Chiller

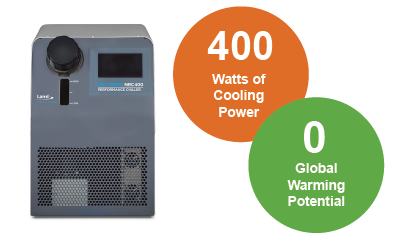

The NRC400 Nextreme™ Performance Chiller is a premium thermoelectric chiller based on high-performance heat exchanger technology. By utilizing next-generation thermoelectric coolers it delivers 400 Watts of cooling capacity and a temperature control accuracy of ±0.05°C under steady state conditions.

The intuitive easy-to-use LCD touchscreen display allows laboratory technicians to easily program temperature set points and alarm features. The NRC400 is a semi-closed system which prevents air from seeping into the liquid circuit, reducing algae growth. Equipped with a larger reservoir tank, the NRC400 requires less refilling during operation and improved temperature stability.

Compared to previous versions, the NRC400 achieves a higher coefficient of performance (COP) at a quieter operation. The solid-state thermoelectric technology offers less moving parts, minimizing maintenance requirements throughout the product lifetime.

Offering a compact form factor in a portable design, the NRC400 can be used on multiple pieces of equipment in the facility.

The NRC400 has been verified by UL for laboratory use and is CE and RoHS compliant. Thermoelectric-based chillers are the most environmentally friendly chiller option as no harmful HFC refrigerants are being used.

Conclusion

Microscopy technology is constantly improving with better detectors to enhance image reconstruction, speed up image acquisition and reduce the size of the equipment. Thermoelectric chillers are used for precise temperature control of heat-sensitive electronics in any type of microscopy equipment. Laird Thermal Systems’ NRC400 Thermoelectric Chiller provides sophisticated and precise cooling of laboratory imaging systems to maximize image resolution, reduce maintenance, and lower the total cost of ownership.

More information on the NRC400 can be found on the Laird Thermal Systems website.