Introduction

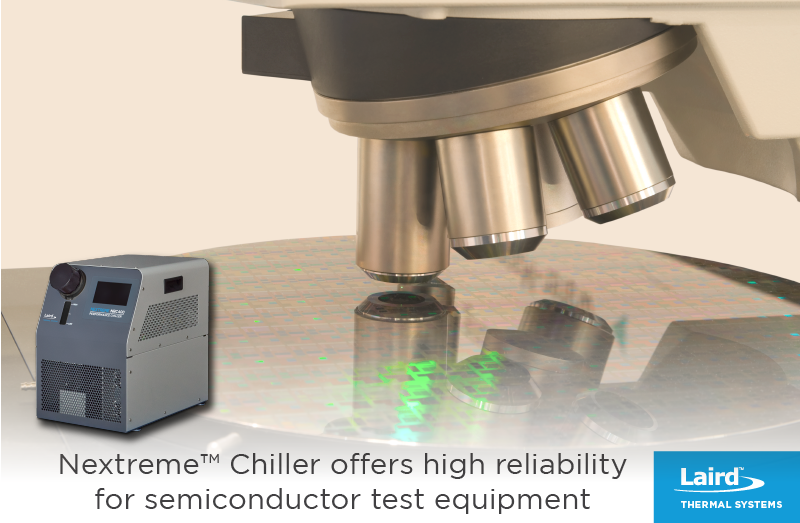

The implementation of automated metrology systems has been a key to achieving cost effective semiconductor fabrication. The complex nature of semiconductor fabrication requires multiple tests between processing steps to inspect defects as well as measure dimensional properties including thickness, refractive index, resistivity and stress of the thin films. Because thermal noise can impact the image resolution of sensitive optical components in automated metrology systems, a thermal management system is required. Temperature fluctuations can also shorten the lifetime of thermally sensitive components, which can result in production downtime and revenue loss. Thermoelectric-based recirculating chillers offer precise temperature control of semiconductor metrology & inspection systems.

Background

Increasing demands for electronic devices has grown the semiconductor fabrication market into a $500 billion industry annually. The semiconductor fabrication process has been one of constant process improvements driving new equipment to allow for manufacturing of 5 nm semiconductors. The implementation of automated optical inspection systems has been the key to achieving cost effective high-volume production. These systems do not only measure the physical properties of the films but also feeds this measurement data back into the manufacturing process. Utilizing imaging sensors, modern metrology inspection systems provide live feedback of local process conditions to the process tool. This data can be used to control the process parameters of the system or to stop the line when an out-of-tolerance measurement occurs.

Enhanced manufacturing processes such as automated optical inspection systems have enabled production of 5 nm semiconductors.

Application Challenges

The need for higher quality, higher packaging density and repeatability combined with a high speed optical inspection system places ever increasing demands on the thermal management solution. Temperature fluctuations will lead to bad data, incorrect decisions or conclusions, and significant yield loss.

Temperature Control

Semiconductor automated optical inspection (AOI) systems often use lasers as the source for testing speed and accuracy. Lasers generate large amounts of heat that must be efficiently dissipated away to maintain the desired wavelength. Temperature fluctuations will impact the laser beam, affecting testing accuracy.

Metrology inspection systems based on CCD or CMOS imaging techniques also require tight temperature tolerances as image resolution degrades with increasing temperature. To provide maximum image resolution, sensors must be kept below ambient temperatures with a temperature stability of ± 0.5°C or better. Cooling laser optics and other key components will also reduce maintenance and increase equipment uptime, lowering the total cost of ownership.

Semiconductor automated optical inspection (AOI) systems typically require removal of up to 100 Watts or more and a temperature stability at 20ºC or below with stability greater than 0.01°C.

Reliability

Because automated semiconductor inspection systems often operate 24/7, the cooling system must provide high reliability with minimal downtime. Proper cooling will help maximize equipment uptime, reduce maintenance and lower the total cost of ownership by increasing the mean time between failure (MTBF). This combined with temperature stability of temperature control to very high precision as possible.

Noise & Vibration

Automated optical inspection tools require a cooling system to enable a steady flow coolant to the temperature sensitive components without pulsation. Temperature fluctuations can distort measurement resolution quality as well as the operational lifetime of components. Larger compressor-based systems are typically noisier and use larger pumps which tend to pulsate, which can generate noise and impact image resolution quality. Thermoelectric-based recirculating chillers are equipped with smaller pumps providing lower pulsation and minimizing impact to imaging system.

Environmental Regulations

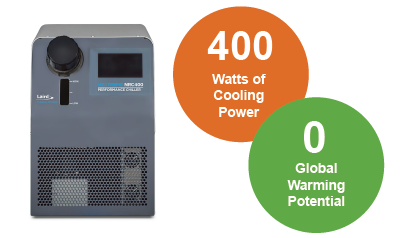

Environmental regulations continue to phase out the use of harmful refrigerants tied to ozone depletion and global warming. Older compressor-based systems use environmentally harmful HFC refrigerants including R134a and R404A. Modern compressor-based systems uses natural refrigerants that have less impact on the environment. Thermoelectric chillers do not use any refrigerants, resulting in zero global warming potential.

Thermoelectric Chiller Solutions

With the ability to cool to well below ambient temperatures, thermoelectric-based recirculating chillers are a better option than passive solutions such as heat sinks and fans or ambient liquid cooling systems. Because of their solid-state operation, they provide high reliability with low maintenance throughout the product lifetime. The plug and play design provides quick and easy installation to any semiconductor metrology equipment.

Utilizing thermoelectric cooling technology, thermoelectric chillers are able to provide very precise temperature control, which is required for spot cooling of metrology inspection system components.

How Does It Work?

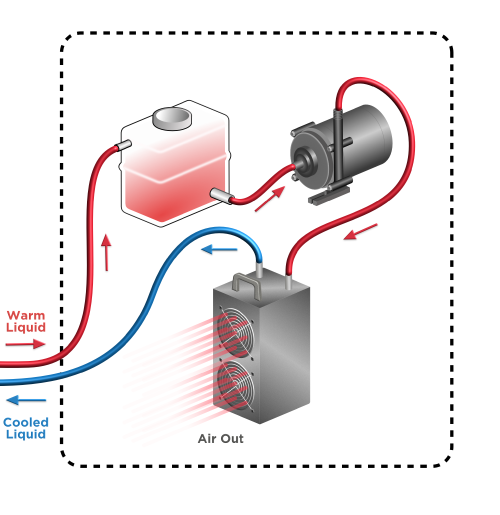

A thermoelectric chiller can cool a metrology imaging tool down to 18ºC while room temperature may fluctuate between 20 and 30ºC. Heat from the system is absorbed by the liquid coolant and flows to a reservoir tank by a pump. The pump pushes coolant thru the Liquid-to-Air thermoelectric engine, which then cools the temperature of the coolant circuit while exhausting waste heat into the surrounding environment. The coolant then flows back to the camera system at a set point temperature where the cold plate is mounted. This is a semi-closed system which reduces algae from building up over time. An ethanol glycol water mixture is recommended to use as coolant to further prevent microbial growth.

Laird Thermal Systems Solution

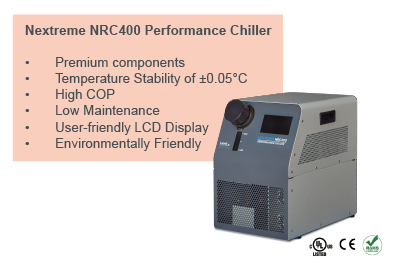

The NRC400 Nextreme™ Performance Chiller is a thermoelectric-based chiller featuring high performance thermoelectric coolers and heat exchanger technology. Utilizing thermoelectric coolers with next generation material, the NRC400 delivers 400 Watts of cooling power and a temperature accuracy of ±0.05°C under steady state conditions.

Compared to previous models, the NRC400 offers a higher coefficient of performance (COP) and lower noise for semiconductor fabrication facilities. Solid-state thermoelectric technology reduces the number of moving parts providing low maintenance requirements throughout the product lifetime.

Traditional compressor-based systems are often large and heavy. Modern cooling systems such as thermoelectric-based chillers are designed with portability in mind, which means that it can be used to cool multiple pieces of equipment in the facility.

The NRC400 features an intuitive easy-to-use LCD touchscreen display that allows users to easily control temperature setpoints and alarm features. The semi-closed system is equipped with a large reservoir tank, requiring less refilling during operation and better temperature stability.

The NRC400 has been approved by UL for industrial lab use, reference UL 61010-1 and has CE marking. It is also RoHS compliant and environmentally friendly as no harmful HFC refrigerants are being used. It operates on a universal power supply, making it easy to source one-part number for global use.

Conclusion

Complex wafer processing has increased the demand for metrology in between the various processing steps. Semiconductor automated optical inspection (AOI) systems require a highly reliable thermal management system that can operate 24/7 and deliver precise temperature control. Thermoelectric-based recirculating chillers are becoming more popular in semiconductor manufacturing processes due to higher reliability and lower operating costs compared to conventional compressor-based systems. A recirculating chiller system utilizing thermoelectric coolers can both heat and cool resulting in better temperature stability for critical applications. The NRC400 thermoelectric chiller maximize performance, reduce maintenance and lower the overall cost of ownership for semiconductor automated optical inspection systems.

More information on the NRC400 can be found on the Laird Thermal Systems website.