Temperature control is critical for medical devices, laser systems, semiconductor metrology and fabrication, additive manufacturing, electron microscopes, and many laboratory instruments used in chemistry, biology, industrial, oil & gas, research, and food science. For example, incubators and cell cultivation applications need temperature control to create the optimal conditions for cell growth, while temperature control plays a dynamic role in ensuring the proper operation of electron microscopes by controlling the temperature of sensitive equipment electronics. Thermal fluctuations can impede the cell growth process within an incubator or degrade the quality of the image within an electron microscope.

Recirculating chillers are liquid cooling systems that precisely control the temperature of water or water with glycol (antifreeze) in a liquid circuit over a broad setpoint and ambient temperature range while removing heat from a process or equipment. This differs from a heat exchanger which cannot cool below the application’s ambient temperature.

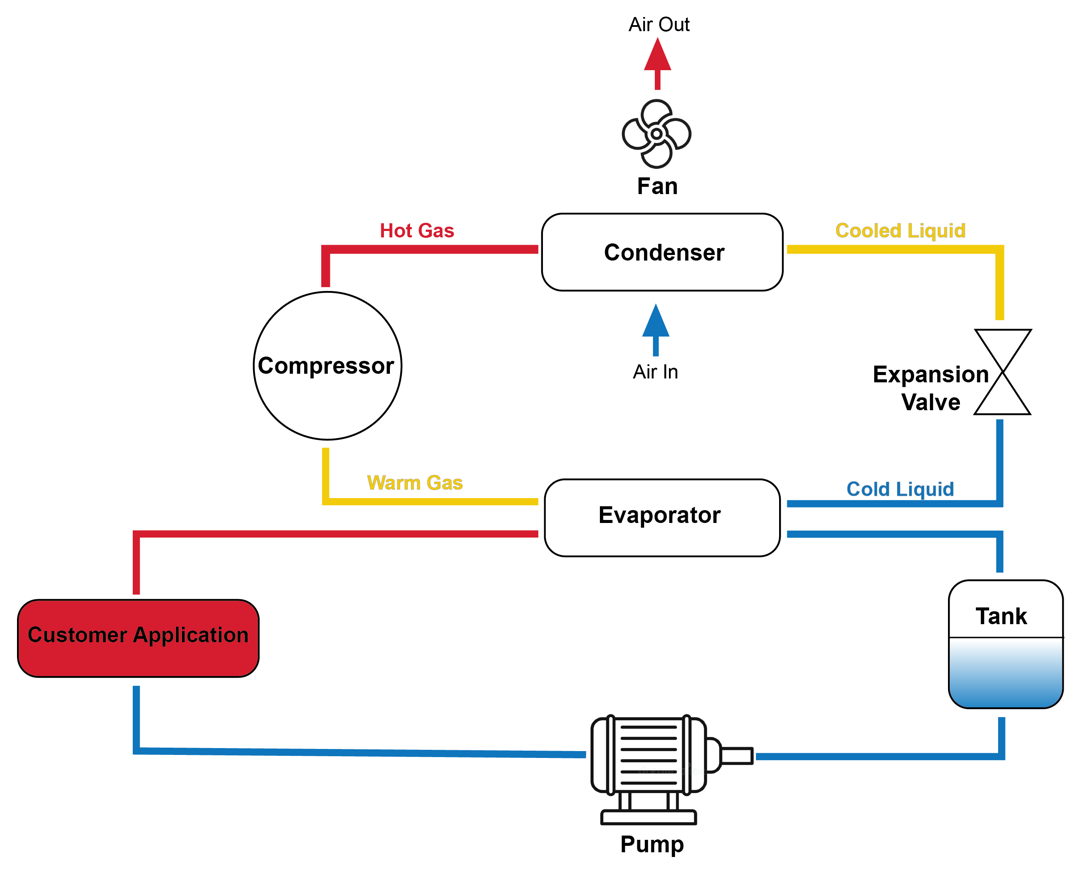

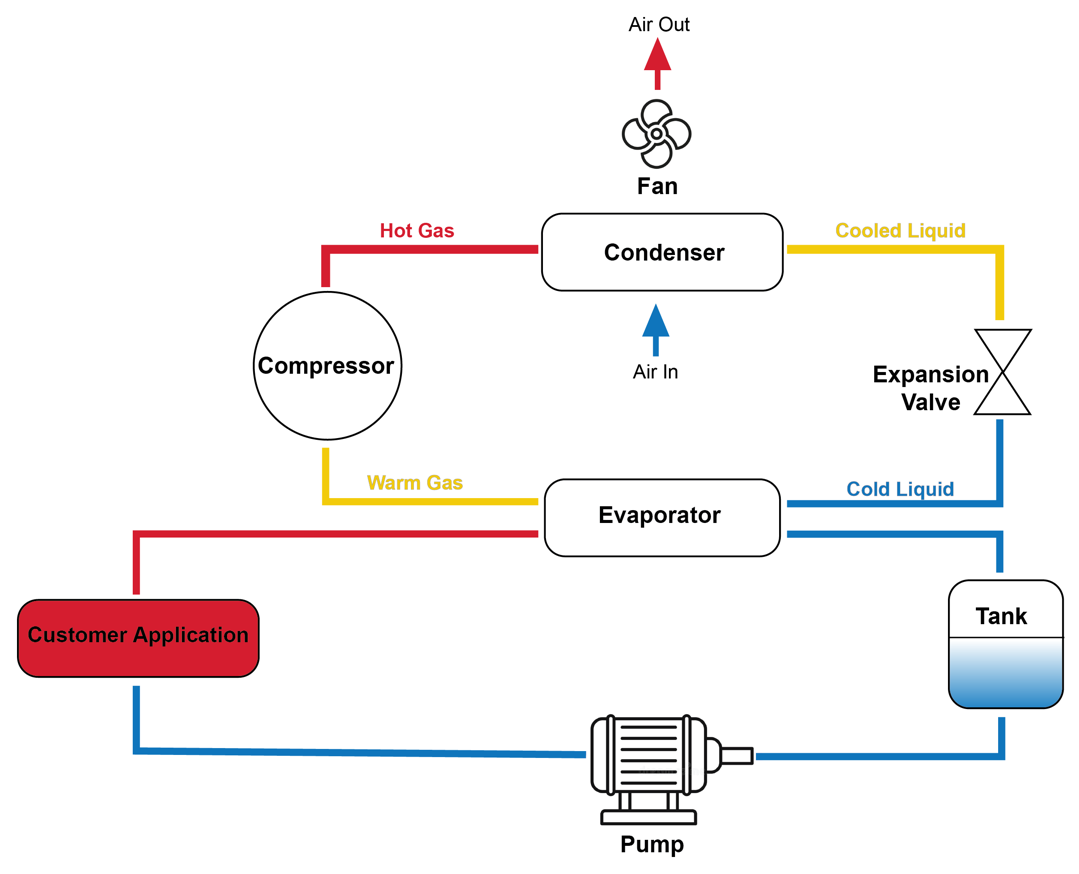

The coolant in a recirculating chiller is recirculated using a high-reliability pump. Heat from the coolant is transferred to an efficient, compressor-based refrigeration system and dissipated to the ambient environment. The main system includes a Tank, Pump, Heat Exchanger (Evaporator), Compressor, Heat Exchanger (Condenser), Fan and Expansion valve, all housed inside a durable sheet metal casing.

When selecting a recirculating chiller, the first thing to know is what are your cooling power (Qc) requirements. Depending on the application and size of the equipment, the amount of cooling power (Qc) required to keep the sensitive electronics and processes in industrial and analytical equipment at an optimum temperature range can vary greatly. Recirculating chiller Qc requirements can range from 400 W to 5000 W and above.

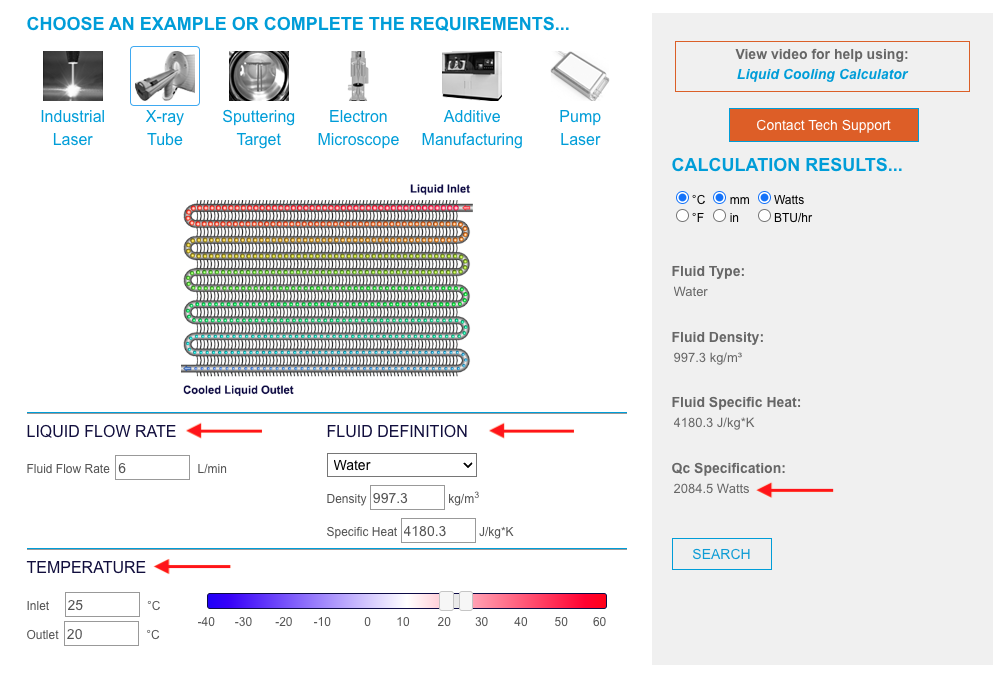

If you do not know the Qc requirement of your application and would like to identify which chiller will perform best in your application, there are tools like the Laird Thermal Systems Thermal Wizard liquid cooling calculator. Access Liquid Cooling and Qc Calculators.

The Thermal Wizard provides a liquid cooling calculator to help you determine the Qc requirement. The Thermal Wizard Cooling Calculator prompts you for all the information necessary to produce a Qc estimate. As you will see, there are 6 examples of applications to help you get started. Once you have determined the Qc requirement, you can utilize the Qc slider to specify the appropriate series of thermal management products and select the optimum solution.

To calculate your application’s Qc requirement, you will need to know the following:

- The liquid flow rate (L/min) of your application

- Identify the cooling fluid to be used (Water, 60/40 Water-Glycol, 50/50 Water-Glycol, other fluid)

- Specify the Density and Specific Heat of the cooling fluid

- Identify the inlet and outlet temperature to determine the temperature differential

In addition to knowing the Qc requirement for your application, you must also know the following:

- Optimum Temperature Range for the chamber, process or component being cooled Liquid Flow Rate

- Fluid Compatibility (is the circulating fluid you’ve selected compatible with the chiller)

- Energy Efficiency (select from chillers that feature a high Coefficient of Performance (COP)

- Installation Requirements (know the footprint of the chiller and that it can be installed safely in the available space)

- Green Lab Requirements (if applicable, is the chiller using an environmentally friendly refrigerant) Read application note on Eco-friendly liquid cooling solutions for today’s lab

Knowing certain factors about your application can help you select the optimum recirculating chiller for your application. With specification and selection tools like the Thermal Wizard or being able to chat live with thermal experts can also help you make a better-informed decision.

Access the Thermal Wizard Specification and Selection Tool

https://lairdthermal.com/thermal-wizard/qc-cooling-selector-home

Related Products

Stay tuned for updates on thermal management industry regulations, new product releases, and innovative temperature control approaches with

LTS Thermal Solutions Spotlight:

Categories

Blog Date