Contents

- Introduction

- The Critical Role of X-Ray Tube Cooling in Medical Imaging

- Custom Liquid Cooling Solutions for X-Ray Systems

- Challenges in X-Ray Tube Cooling

- The Expanding Medical Imaging Market in the APAC Region

- Future Trends and Opportunities in X-Ray Cooling

- Advanced Liquid Cooling System Pump

- Summary

Introduction

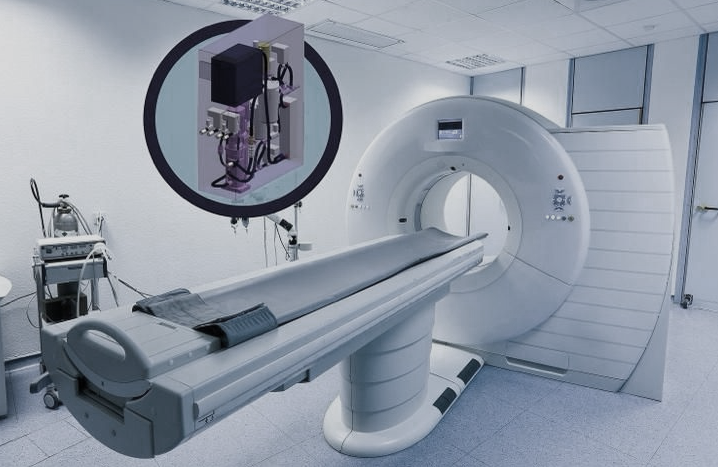

The medical imaging sector, particularly X-ray systems, is rapidly evolving with advancements in resolution, speed, and accuracy. These innovations drive the need for efficient cooling systems. X-ray tubes, a key component in imaging systems like CT scanners, generate significant heat during operation. Proper thermal management, including advanced liquid cooling systems, is vital to maintaining performance, minimizing downtime, and ensuring patient safety.

This technical paper explores the role of custom liquid cooling systems, particularly pumps, in addressing the cooling requirements of X-ray systems. It highlights the importance of tailored cooling solutions in meeting the unique demands of modern medical imaging devices. The paper also discusses the evolving market dynamics, particularly in the Asia-Pacific (APAC) region, where local original equipment manufacturers (OEMs) are becoming increasingly competitive. By examining industry challenges, custom capabilities, and future trends, this paper provides an in-depth look at how advanced liquid cooling systems are helping to shape the future of medical imaging technology.

The Critical Role of X-Ray Tube Cooling in Medical Imaging

X-ray machines, including CT scanners, image-guided therapy (IGT), fluoroscopy units, and other diagnostic imaging systems, are integral to modern healthcare. These machines rely on X-ray tubes to produce the high-energy radiation needed for imaging. However, this process generates significant amounts of heat, which, if not properly managed, can cause overheating, reduce equipment lifespan, and affect image quality. X-ray tubes in medical imaging systems can generate substantial heat loads, reaching up to 5 kW. X-ray generation is a highly inefficient process where only about 1% of the electron beam's kinetic energy is converted into X-rays, while more than 99% of the energy is converted into thermal energy. The heat generated increases with higher exposure time settings, mA (the tube current, which influences X-ray intensity), or kilovoltage peak (kVp). kVp is the maximum voltage applied across an X-ray tube during an exposure. Effective cooling is therefore essential to maintaining the operational efficiency and reliability of these machines.

X-ray machines, including CT scanners, image-guided therapy (IGT), fluoroscopy units, and other diagnostic imaging systems, are integral to modern healthcare. These machines rely on X-ray tubes to produce the high-energy radiation needed for imaging. However, this process generates significant amounts of heat, which, if not properly managed, can cause overheating, reduce equipment lifespan, and affect image quality. X-ray tubes in medical imaging systems can generate substantial heat loads, reaching up to 5 kW. X-ray generation is a highly inefficient process where only about 1% of the electron beam's kinetic energy is converted into X-rays, while more than 99% of the energy is converted into thermal energy. The heat generated increases with higher exposure time settings, mA (the tube current, which influences X-ray intensity), or kilovoltage peak (kVp). kVp is the maximum voltage applied across an X-ray tube during an exposure. Effective cooling is therefore essential to maintaining the operational efficiency and reliability of these machines.

Traditionally, passive cooling methods such as heat sinks and fans were used to manage heat in smaller systems. However, the increased power and complexity of modern X-ray systems require more advanced cooling solutions. Liquid cooling, which transfers heat away from the X-ray tube more efficiently than air cooling, has become the preferred method for high-end medical imaging devices. This is due primarily to the following advantages:

- Improved Heat Transfer Efficiency - due to the superior specific heat capacity and thermal conductivity of liquid coolants, liquid cooling systems can dissipate heat 50 to 1,000 times more efficiently than air cooling depending on the specific liquids and cooling designs used.

- Compact Design - liquid cooling systems can be more compact than air-based systems, making hem ideal for the limited space available in medical imaging equipment.

- Longer Equipment Lifespan - by maintaining optimal operating temperatures, liquid cooling systems can extend the life of X-ray tubes and other critical components.

Custom Liquid Cooling Solutions for X-Ray Systems

Each X-ray system has unique thermal management requirements, depending on factors such as size, power, and application. As a result, custom liquid cooling systems are relied upon to ensure optimal performance by meeting the specific thermal needs of a given X-ray machine in addition to addressing the challenges of compact enclosures, and stringent reliability requirements. The key components of today’s custom liquid cooling systems often include custom coolants, advanced pumps and compact, flexible designs.

Each X-ray system has unique thermal management requirements, depending on factors such as size, power, and application. As a result, custom liquid cooling systems are relied upon to ensure optimal performance by meeting the specific thermal needs of a given X-ray machine in addition to addressing the challenges of compact enclosures, and stringent reliability requirements. The key components of today’s custom liquid cooling systems often include custom coolants, advanced pumps and compact, flexible designs.

Custom Coolants for liquid cooling systems are often used to optimize thermal conductivity, viscosity, and corrosion resistance. These coolants include oil-based, ethylene glycol, propylene glycol, or specialized dielectric fluids and can be tailored to the specific operating conditions of the X-ray machine.

Advanced custom pumps are the heart of any liquid cooling system, circulating the coolant through the system to ensure consistent heat removal. Their performance has a direct impact on the overall efficiency and reliability of the cooling system. In X-ray systems, pumps are responsible for circulating coolant through the heat exchangers, ensuring that heat is transferred away from the X-ray tube and other components. In high-performance X-ray systems, custom pumps must be durable enough to withstand the mechanical stresses associated with high rotational speeds and pressures. They are designed to handle high flow rates (up to 30 liters/minute), pressures (29 – 145 psi), and rotational speeds between 10-75 G. The design of these pumps must be robust enough to operate reliably over long periods while maintaining the efficiency of the cooling system.

Advanced custom pumps are the heart of any liquid cooling system, circulating the coolant through the system to ensure consistent heat removal. Their performance has a direct impact on the overall efficiency and reliability of the cooling system. In X-ray systems, pumps are responsible for circulating coolant through the heat exchangers, ensuring that heat is transferred away from the X-ray tube and other components. In high-performance X-ray systems, custom pumps must be durable enough to withstand the mechanical stresses associated with high rotational speeds and pressures. They are designed to handle high flow rates (up to 30 liters/minute), pressures (29 – 145 psi), and rotational speeds between 10-75 G. The design of these pumps must be robust enough to operate reliably over long periods while maintaining the efficiency of the cooling system.

Custom liquid cooling systems must be designed to fit within the tight spaces often encountered in medical imaging systems. These systems can be configured to accommodate specific spatial and mechanical constraints, ensuring compatibility with the overall machine design.

Challenges in X-Ray Tube Cooling

Despite the opportunities in the medical imaging market, there are several challenges facing thermal management providers associated with cooling X-ray tubes and ensuring the long-term reliability of imaging systems. These challenges include high heat loads, pump reliability, space constraints, system integration and perhaps the most important challenge, cost pressures.

The increasing pressure to reduce the cost of medical imaging systems, particularly in China and other APAC markets where competitive pressures are high, requires the development of simple, cost-effective cooling solutions that do not compromise the performance or reliability of the equipment.

Local OEMs have minimized costs by leveraging domestic supply chains, adopting modular cooling designs, and integrating cost-efficient materials. Cooling systems must be seamlessly integrated into the overall design of the X-ray machine, ensuring that all components work together efficiently. This includes careful consideration of factors such as coolant flow, pressure, space and temperature regulation, in order to provide effective thermal management.

The Expanding Medical Imaging Market in the APAC Region

The medical imaging market in the APAC region, particularly in China, has seen remarkable growth in recent years. This expansion is driven by several factors, including government initiatives, an increasing demand for healthcare services, driving the increase in number of local CT scanner OEMs. A decade ago, global players like GE, Siemens, and Philips dominated the medical imaging market in China. However, today, local manufacturers such as United Imaging and Neusoft have become key competitors, capturing significant market share.

As local manufacturers improve their capabilities, they are increasingly developing their own X-ray technologies, including the production of X-ray tubes and cooling systems. This shift is partly due to the Chinese government’s efforts to reduce reliance on imported medical equipment and to support the development of domestic medical technologies. Government initiatives to build new hospitals and upgrade existing healthcare infrastructure have created significant demand for locally produced medical imaging systems. Furthermore, the cost of locally manufactured X-ray systems is often significantly lower than that of imported systems, further driving the adoption of domestic technologies.

Advanced liquid cooling systems tailored to the needs of local OEMs, can play a key role in supporting the growth of the domestic medical imaging market. Moreover, manufacturers like Laird Thermal Systems with engineering, manufacturing and local supply chains in APAC, America and EMEA can leverage their global expertise, and help local OEMs develop high-performance systems that meet international standards.

Future Trends and Opportunities in X-Ray Cooling

Looking ahead, several key trends are shaping the future of X-ray cooling systems. One emerging technology in high-end X-ray tubes is the use of liquid metal bearings. These bearings offer increased durability and reduced friction, but they also place greater demands on the cooling system. Custom cooling solutions will need to be designed to accommodate the changes in thermal management of the X-ray tube associated with these bearings.

As medical imaging systems become more complex, OEMs will increasingly require highly customized cooling solutions that are tailored to the specific needs of each system. This will create opportunities for companies that can offer flexible, scalable cooling solutions. The push for cost reductions, particularly in markets like China, will continue to drive demand for affordable cooling solutions. Companies that can manufacture high-performance cooling systems in multiple regions at competitive prices will be well-positioned to succeed in this market.

As sustainability becomes a greater concern in the medical industry, there will be an increasing focus on developing energy-efficient cooling systems that minimize environmental impact. Sustainability efforts include the use of recyclable coolants and the development of energy-efficient cooling systems.

Laird Thermal Systems Custom Solutions

Liquid cooling systems offer a high coefficient of performance (COP) that delivers efficient, low power operation to maximize uptime and optimize performance of medical X-ray imaging equipment. This efficiency optimizes heat transfer delivery away from thermally sensitive components to the ambient environment. A liquid cooling system offers higher efficiency than air-based heat exchangers providing faster cooling, quieter operation, higher reliability, and increased system uptime. As mentioned earlier, liquid cooling systems are much more efficient at dissipating heat compared to conventional air heat transfer mechanisms,. Laird Thermal Systems’ liquid cooling systems feature high thermal conductivity of coolants to remove bulk heat in Kilowatts in compact designs with quiet operation.

Since medical X-ray equipment features many unique cooling challenges, a custom liquid cooling system configuration is often required to optimize performance and provide long-life operation. The type of coolant used in these applications will often depend on the material compatibility. Laird Thermal Systems has the experience to design cooling systems that are compatible with water, water-glycol, dielectric oil or various corrosion inhibitors. Liquid cooling systems can also be quite complex and require temperature control of multiple liquid circuits or multiple pressure drop settings in order to accommodate low and high-pressure conditions. From simple cooling systems to complex and precise temperature control systems with multiple liquid circuits or multiple pressure drop settings, Laird Thermal Systems offers dynamic solutions that meet medical X-ray application requirements. With global engineering design services and validation test services that support onsite concept generation, thermal modeling, mechanical and electrical design and rapid prototyping, Laird Thermal Systems meets the unique compliance standards for the medical industry.

Advanced Liquid Cooling System Pump

Our centrifugal water pumps are engineered to deliver exceptional performance in the most demanding environments, providing reliable cooling and fluid management for critical applications, including medical imaging, industrial operations, and security scanning systems. Featuring a robust 125-watt output, these pumps ensure consistent, optimal cooling for systems requiring continuous operation. Designed with dual voltage input (115/230V AC) and 50/60Hz frequency compatibility, they offer seamless global integration, making them ideal for international use. The fully submersed oil pump design enhances durability, protecting the pump against moisture and heat while ensuring safe, long-term operation in challenging conditions.

With a design optimized for low maintenance and extended lifespan, centrifugal pumps provide a cost-effective and reliable cooling solution. Their ability to operate in the most challenging conditions makes them an indispensable component in safeguarding the performance and longevity of heat-sensitive systems like medical imaging applications.

Summary

The medical imaging market is evolving rapidly, driven by advancements in technology and increasing demand for high-performance imaging systems. Effective thermal management is essential to ensuring the long-term reliability and performance of these systems, and custom liquid cooling solutions, including pumps, play a critical role in this process.

As the market continues to grow, the need is increasing for advanced, cost-effective, locally manufactured cooling solutions. By providing custom cooling solutions, companies like Laird Thermal Systems can meet the diverse needs of OEMs in the medical imaging industry, helping them deliver the highest levels of performance and patient care, reliability, and cost-effectiveness.

Learn more about custom solutions here:

Custom Liquid Cooling Solutions

About Laird Thermal Systems

Laird Thermal Systems develops thermal management solutions for demanding applications across global medical, industrial, transportation, and telecommunications markets. We manufacture one of the most diverse product portfolios in the industry, ranging from active thermoelectric coolers and assemblies to temperature controllers and liquid cooling systems. Our engineers use advanced thermal modeling and management techniques to solve complex heat and temperature control problems. By offering a broad range of design, prototyping, and in-house testing capabilities, we partner closely with our customers across the entire product development lifecycle to reduce risk and accelerate their time-to-market. Our global manufacturing and support resources help customers maximize productivity, uptime, performance and product quality. Laird Thermal Systems is the optimum choice for standard or custom thermal solutions. Learn more by visiting www.lairdthermal.com.

Contact Laird Thermal Systems

Have a question or need more information about Laird Thermal Systems? Please contact us via the website.