Introduction

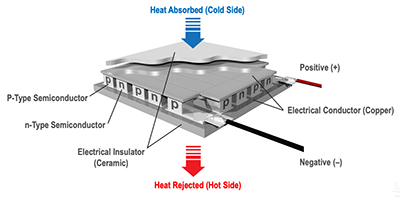

The use of outdoor cameras has seen a massive influx with the rise in security monitoring by government and private security agencies. Security cameras are installed with an objective to reduce crime or to improve public safety. CCTV and IP security cameras are installed on every corner in cities, outside hotels and retail stores, all around entertainment venues, stadiums and other commercial and industrial properties. Thermal cameras (infrared sensing) are now often used to improve facility and boarder security at night. Most recently, thermal cameras have been implemented to detect people’s body temperatures as a security and safety measure in the fight against COVID-19. No matter the camera technology implemented, it is critical that the optimum operating temperature of sensitive imaging components is maintained during use to ensure high quality images. Active thermoelectric coolers utilizing the Peltier effect offer advanced thermal management solutions. These thermoelectric devices meet the size constraints and high temperature rating required for optoelectronics implemented in outdoor security cameras.

Active cooling is required to control temperature of critical components in outdoor security cameras

Application Growth

According to Markets and Markets, the global video surveillance market size is expected to grow from USD 45.5 billion in 2020 to USD 74.6 billion by 2025. Increasing concerns about public safety and security, growing adoption of IP cameras, and rising demand for wireless and spy cameras are the factors driving the growth of the video surveillance industry. Allied Market Research is projecting this growth to be at $144.85 billion by 2027.

Global Markets Insights reports that the IP camera market size alone was valued at over USD 8 billion in 2018 and will grow at a compound annual growth rate (CAGR) of 14% from 2019 to 2025. The global industry shipments are expected to exceed 100 million units by 2025.

Global Markets Insights also claims that the Infrared camera market size exceeded USD 6 billion in 2019 and is set to grow at 7% CAGR between 2020 and 2026. The global industry shipments are projected to reach 3.5 million units by 2026 owing to increasing deployment of cameras for all-weather and lighting surveillance purposes in various end-use sectors.

Application Background

Digital security cameras use two main types of imaging sensors: CCD (charge-coupled device) sensors and CMOS (complementary metal-oxide semiconductor) sensors. Both sensors convert light (photons) into an electrical charge (electrons) using an intricate 2-D array of photo-detectors (pixels). These individual buckets of charge are then amplified and digitized to create the digital image. The difference between the two main types of sensors is how and where this is accomplished.

Many security cameras are now implementing thermal imaging technology for detection at night. These cameras create an image using infrared radiation (heat), similar to a common camera that forms an image using visible light. Instead of the 400–700 nanometer range of the visible light camera, infrared cameras are sensitive to wavelengths from about 1,000 nm (1 μm) to about 14,000 nm (14 μm). Thermal imaging cameras use focal plane arrays (FPAs) that respond to longer infrared wavelengths. Some smart thermal cameras include powerful video processors with access to the raw thermal video as it leaves the imager for more accurate detection. Advanced video processing also gives thermal cameras extended range and coverage, detecting human-sized targets at ranges exceeding 600 meters.Thermographic cameras can be broadly divided into two types: those with cooled infrared image detectors and those with uncooled detectors. Cooled detectors exist to maximize detection performance and viewing range.

3D cameras enable the perception of depth in images to replicate three dimensions as experienced through human binocular vision. Some 3D cameras use two or more lenses to record multiple points of view, while others use a single lens that shifts positions. While 2D camera inspection detects or differentiates appearance or dimension based on shade data, 3D inspection incorporates height information (XYZ coordinates). Utilizing XYZ coordinate data makes it possible to obtain volume and sectional area information. 3D inspection detects minute flaws that look similar to patterns on the target, which were difficult to differentiate with conventional 2D imaging. As 3D camera technology enhances, the number of applications increases. 3D Cameras are commonly used in robotic positioning, automation inspection, and character recognition for manufacturing and testing applications and are now being introduced to sports stadiums and entertainment venues to improve attendee experience.

Challenges

Engineers can face a variety of thermal challenges when designing outdoor security cameras including thermal noise, size constraints, lack of airflow, and outgassing.

Traditional CCTV and IP outdoor cameras operate efficiently at temperatures up to 50⁰C, but the performance degrades as the temperature increases beyond this limit. Infrared cameras also require operating temperatures to be below 50⁰C before imaging accuracy is affected. Outdoor camera applications may see operating temperatures as high as 90°C due to the direct exposure to sun and heat generated by surrounding components in a compact form factor.

Depending on the imaging requirements, cameras may contain several CMOS sensors to enhance resolution or capabilties. For example, new 3D cameras have four CMOS sensors to generate high quality 3D images. The internal electric power from more intricate 3D camera systems can generate more than 60 Watts of heat. Add in solar radiation and the outdoor 3D camera components are tasked with operating well above their thermal temperature limits. The camera system must be cooled to minimize heat generation, with priorites to cooling each CMOS sensor to below its thermal tolerance in order to optimize image quality. This requires a cooling solution with enough cooling capacity to efficiently cool four sensors and dissipate heat away from all sensitive electronics into the ambient environment.

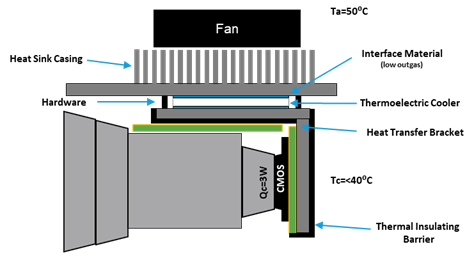

2-D diagram of CMOS cooling application.

Thermal cameras are extremely sensitive to thermal noise. Since thermal cameras are detecting radiated heat, any heat from passive components themselves makes it harder to capture images. Thermal management systems must quickly dissipate heat away from the internal camera components, including the sensor and video processors. High functioning thermal management systems will enable IR cameras to detect thermal energy with an accuracy as fine as 0.025°C.

The trend toward miniaturization of cameras is another factor that affects the heat load. To increase capabilities and functionality, modern security cameras feature more electronics in smaller enclosures. Space constraints can negatively affect air flow while increasing the heat flux density. Limitations to proper airflow result in an inefficient design that only cools several degrees above ambient. This temperature may be above the image sensor’s maximum operating temperature limit. Cooling components, like thermoelectric devices, can also add heat to the heat rejection path, requiring a heat exchanger with more capacity to dissipate heat into the air environment. It is important for a design to consider airflow that sufficiently dissipates heat to keep down the thermal resistance of the hot side heat exchanger. Fans or liquid heat exchangers add costs and require space within an already space-constrained design, which can prove challenging.

Also affecting airflow are camera designs that completely seal the camera components. This is done to enable the camera to withstand outside elements such as water or fluids and dust or dirt. Completely sealed cameras pose a significant challenge, routing heat out of the enclosure away from thermally sensitive components. Most often, the enclosure must feature a cold plate that conducts heat through a heat sink or heat pipes to transfer heat.

Cooling vital components can result in the creation of condensation. Surfaces exposed to temperatures below dew point will develop unwanted and potentially harmful moisture. Outgassing must be avoided at all costs, as it can fog the security camera lenses. Creating protective exteriors to prevent moisture, condensation, and the ingress of other outside contaminants is critical in protecting sensitive camera electronics.

Traditional Solutions

Standard heat sinks cannot cool below ambient and do not offer enough cooling capacity as a standalone unit to meet outdoor camera thermal requirements. Active thermoelectric devices such as thermoelectric coolers are used in conjunction with passive heat sinks to offer spot cooling and rapidly move heat away from sensitive electronics. Standard thermoelectric coolers can create a temperature differential across it, which lowers the temperature differential of the critical device by as much as ~30°C from hot side temperature of heat exchanger. Heat will then need to be routed thru a heat rejection mechanism, such as a heat sink and fan, to get the heat transferred into the air environment. However, it is critical that the hot side heat sink does not saturate. Otherwise heat will flow back into the device and heat it up. This is why optimization for high coefficient of performance (COP) is critical.

Because traditional thermoelectric devices cannot operate efficiently in extreme outdoor temperatures, spot cooling of the imaging sensors in security camera applications is no easy task. At high temperatures, materials used in the installation of the thermoelectric device, including solder, copper and the busbar, will diffuse into the thermoelectric device. This will cause the standard thermoelectric device to ultimately fail.

Thermoelectric Coolers utilize the Peltier Effect to efficiently dissipate heat from sensitive electronics.

Laird Thermal Systems™ HiTemp ETX Series

The HiTemp ETX Series thermoelectric cooler has a robust construction that allows it to survive in temperatures up to 150⁰C, exceeding most outdoor applications. It is assembled with advanced thermoelectric materials that boosts cooling capacity by up to 10% compared to traditional thermoelectric coolers. These solid-state heat pumps feature a higher thermal insulating barrier when compared to standard thermoelectric materials creating a maximum temperature differential (ΔT) of up to 83°C.

The enhanced thermoelectric materials are combined with a proprietary construction that prevents performance degradation in high temperature environments, a common problem with standard grade thermoelectric coolers. The HiTemp ETX Series maintains a high coefficient of performance (COP) to minimize the amount of input power required to operate and reduces the heat rejection requirement to the hot side, which is critical in poor heat sinking applications.

The HiTemp ETX Series is available in over 50 models covering various footprints, cooling capacities, voltage ranges and finishing options.

Laird Thermal Systems™ HiTemp ETX Series can survive temperatures up to 150⁰C.

Conclusion

Temperature sensitive optoelectronics continue to be specified in outdoor applications with worst case temperatures exceeding 90⁰C. Heat fluctuation in these critical systems can cause degradation of performance, and even system failure. These devices, like outdoor security cameras, require active cooling to keep below their maximum operating temperature in outdoor environments. However, standard thermoelectric devices cannot operate in these high temperatures either. New materials have been designed into the HiTemp ETX Series that allows it to operate in temperatures up to 150⁰C, exceeding most outdoor applications.

More information on the HiTemp ETX Series can be found by visiting

lairdthermal.com/hitemp-etx-series