Vertical-cavity surface-emitting lasers (VCSELs) are a type of semiconductor laser that emits a circular, low-divergence beam of light perpendicular to the surface of the chip, as opposed to edge-emitting lasers that emit parallel to the chip surface. This beam quality simplifies optical system design and improves coupling efficiency. VCSELs are characterized by their unique structure, which consists of a thin layer of active semiconductor material sandwiched between two highly reflective mirrors. VCSELs offer several advantages over traditional edge-emitting lasers, including low-power consumption, high-speed operation, wide wavelength range, ease of integration, and lower cost. Traditionally VSCELs are resilient to temperature changes and are highly stable. However, the emergence of high-powered VSCELs is driving the need for temperature stabilization in some applications.

VCSEL Background

VCSELs found widespread adoption in the late 1990s and early 2000s. VCSELs’ high modulation bandwidth allows for high-speed data rates, which makes them well-suited for applications such as optical communication systems and high-speed interconnects. VCSEL technology has continued to evolve and are now also used in biomedical imaging, 3D sensing, laser printing and other industrial applications.

Historically, VCSEL applications have utilized GaAs wafers, however new applications including augmented reality, virtual reality, biosensing, datacom and LIDAR, have established a market for high-powered VSCELs that use InP wafers. InP wafers offer many benefits for high-power VCSEL applications including higher frequency operations, wider bandgap, lower noise and higher thermal resistance and better conductivity.

According to Prescient & Strategic Intelligence, the global market for VCSELs was US$1.5 billion in 2021, and is projected to reach US$6.96 billion by 2030. This growth is primarily attributed to the adoption of 3D sensing features in smartphones and autonomous vehicles (LiDAR and ADAS).

VCSEL Cooling Challenges

As noted previously, traditional GaAs VSCELs are very stable in temperature change environments. They work from 600 to 1200 nm. High-powered InP VCSELs operate at a higher wavelength spectrum of 1200 to 1800 nm and cover further distances. In consumer applications, using a higher wavelength spectrum reduces susceptibility to sunlight, is eye safe at 10X the power and has lower absorption through OLED displays.

High-power VCSELs generate more optical power, resulting in higher power densities within the device. This increased power density leads to a greater amount of heat generation per unit volume, making the device more susceptible to thermal issues. Changes in temperature can shift the laser wavelength and reduce output power affecting performance and lifespan. Excessive heat can lead to accelerated aging and reduced reliability of VCSELs. Ensuring proper cooling through effective thermal management is essential for maintaining consistent performance and extending the operating life of these devices.

When the temperature fluctuates, VCSELs can also exhibit mode hopping behavior (the abrupt transition of the laser output from one mode to another). This can be problematic in applications requiring stable and continuous laser emission. As InP VCSELs are scaled up in power output, the cooling requirements become more challenging.

It is important to note that the majority of InP VSCEL applications do not require external cooling technologies. High-power, ultra-high performance, InP-based applications require advanced temperature stabilization solutions for precise temperature control to manage the increased heat load.

VCSEL Cooling Solutions

The cooling solution of choice depends on the specific requirements of the application such as power requirements, size constraints, and thermal management goals. In addition, VCSELs have a thermal resistance that determines how effectively heat can be conducted away from the device. High thermal resistance can limit the power output and efficiency of the VCSEL, therefore thermal design considerations are essential to minimize thermal resistance and enhance overall performance.

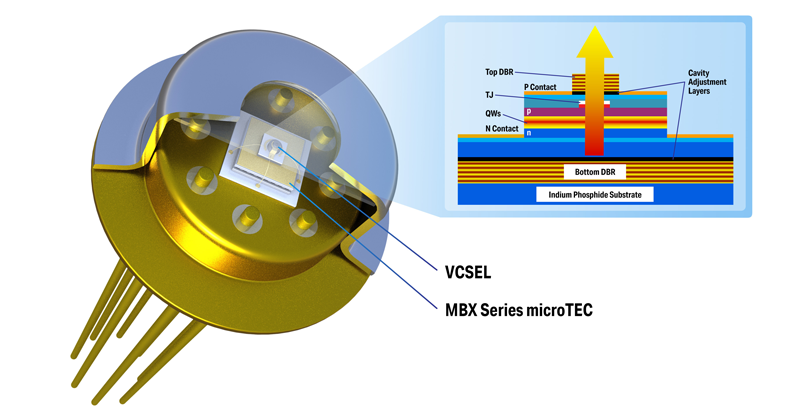

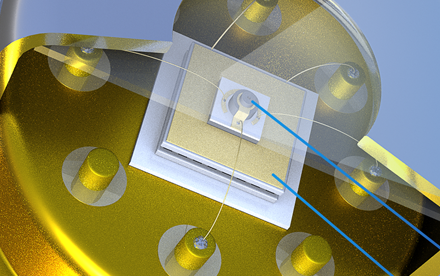

VCSEL laser diode packages demand advanced cooling, requiring micro thermoelectric coolers with enhanced heat pumping capacity. Recent innovations in thermoelectric materials and manufacturing processes have enabled slimmer thermoelectric cooler profiles. This innovation allows the production of smaller form factor laser diodes without compromising thermal stability. Laird Thermal Solutions' smaller and cost-effective OptoTEC™ MBX series, meets modern VCSEL requirements, offering reduced size, lower power consumption, heightened reliability, and cost-efficient production. These features enhance laser diode performance, promoting innovation in next-gen telecom applications.

_(with-call-outs).png)

TO-Can with integrated VCSEL and micro-TEC for cost-effective, reliable cooling

Applications

The goal of the thermal management solution is to keep VCSELs within their specified operating temperature range to achieve reliable laser emission, proper wavelength control, and optimum performance. Applications like those mentioned below require precise temperature control often under tight space constraints making ultra-small thermoelectric coolers an ideal cooling candidate.

Data Communications: VCSELs are commonly used in high-speed data communication applications, such as optical transceivers for data centers and fiber-optic networks. In these applications, precise temperature control is essential to maintain the laser's output wavelength stability, which is critical for reliable data transmission at high data rates.

3D Sensing and LiDAR: VCSELs are utilized in 3D sensing technologies like facial and gesture recognition. They are also used in LiDAR (Light Detection and Ranging) systems for autonomous vehicles. To achieve accurate depth sensing and distance measurements, VCSELs must emit light at a consistent wavelength and power. Active cooling and temperature regulation are necessary to minimize wavelength drift and ensure reliable operation in varying environmental conditions.

Biomedical Imaging: VCSELs are used in medical devices for applications such as optical coherence tomography (OCT) and fluorescence imaging. Precise temperature control is vital to maintain wavelength stability and optimize the quality of imaging results.

Printing and Imaging: VCSELs are used in high-quality laser printing and imaging applications. Active cooling and thermal control are necessary to maintain consistent print quality, prevent color shifts, and ensure long-term reliability in demanding printing environments.

Sensors and Metrology: VCSELs are utilized in various sensing and metrology applications, including environmental monitoring, industrial automation, and precision measurement devices. Maintaining the stability of VCSELs ensures accurate and repeatable measurements over time.

Consumer Electronics: VCSELs are being increasingly integrated into consumer electronics, such as smartphones for facial recognition and depth sensing. Because smartphones are subjected to varying ambient temperatures, active thermal management is required to maintain the performance and reliability of the VCSEL-based sensors.

Industrial Laser Systems: VCSELs are being used in industrial laser systems for material processing, cutting, and marking. In these applications, active thermal management is crucial to maintain laser power and beam quality, ensuring consistent results in the manufacturing process.

Quantum Technologies: In emerging quantum technologies like quantum computing and quantum communication, VCSELs play a role in generating and manipulating quantum states of light. Active thermal management helps stabilize the VCSELs' performance, contributing to the reliability of quantum systems.

Related Products

Stay tuned for updates on thermal management industry regulations, new product releases, and innovative temperature control approaches with

LTS Thermal Solutions Spotlight:

Categories

Blog Date