Cooling for Centrifuges

A centrifuge is a laboratory device using centrifugal force to separate liquid mixtures.

Quick Links

To separate fluids, the centrifuge spins samples at a fast rate, resulting in heavy components to migrate away from the center axis and lighter components to migrate towards the axis. Centrifuge devices are widely used tools in food processing and medical research for cellular, genetic and protein analysis. When designing laboratory and medical centrifuges, several design challenges must be considered.

Many samples, such as live cells, tissues and proteins, are temperature sensitive. They must be stored and tested at precise temperatures to ensure proper reaction and viability. Additional design challenges include reduced footprints, noise levels, vibration and power consumption. In addition, many governments have restricted the use of traditional and natural refrigerants central to compressor-based systems.

To ensure precise temperature control for laboratory and medical centrifuge applications, active thermoelectric coolers and assemblies are more advantageous solutions for centrifuges compared to compressor-based systems. Peltier-based thermal management systems deliver stable and reliable performance at a lower total cost-of ownership.

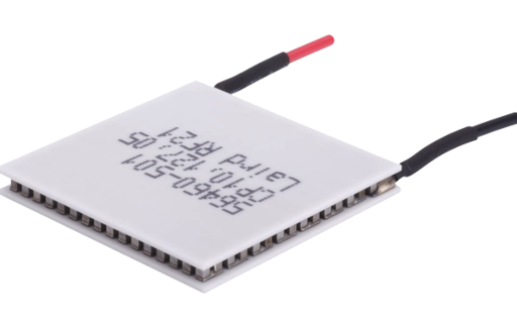

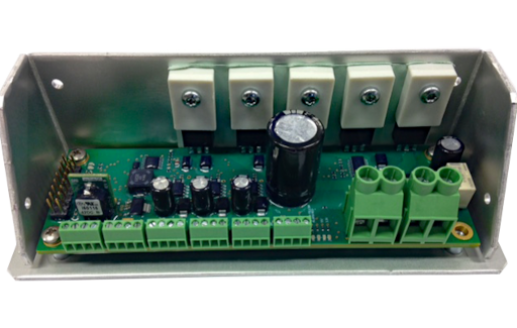

Laird Thermal Systems’ Ceramic Plate (CP) Series is a rugged, compact thermoelectric cooler designed for higher current and large heat-pumping applications like benchtop and high-speed centrifuges. When higher cooling capacities are required, the Tunnel Series and SuperCool X Series thermoelectric cooler assemblies are the ideal solution. For precise temperature control, fast ramp rates and cooling below ambient temperatures, these units can be combined with Laird Thermal Systems’ SR-54 Series or PR-59 temperature controllers.