Heating and Cooling of Incubator Chambers

Incubators used in hospital and laboratories are designed to provide the optimal environment for cell growth.

Quick Links

Since proteins are extremely sensitive to environmental deviations, a temperature difference by as little as 6°C from the body temperature of 37°C, have a negative impact on cell health. If too cold, cell growth slows and if too hot, sensitive proteins begin to denature. Not only temperature needs to be controlled, also humidity, carbon dioxide and oxygen levels are important factors. Due to the limited space constraints within incubators, thermal solutions must have a compact form factor. Incubator manufacturers also face challenges related to airflow, moisture, dust and ease of cleaning. Thermoelectrics deliver an efficient, thermally stable, compact, reliable, low-maintenance, low-cost-of-ownership solution for incubator temperature control. Unlike traditional compressor-based technologies, Peltier thermoelectrics are environmentally friendly. Recent government regulations banning the use of specific refrigerants, particularly in Europe, are motivating incubator manufacturers to look at solid-state thermoelectric temperature control systems as an alternative to compressor-based systems.

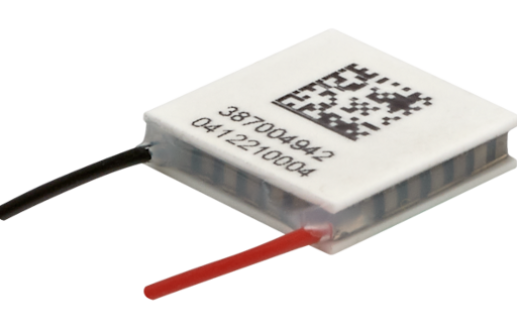

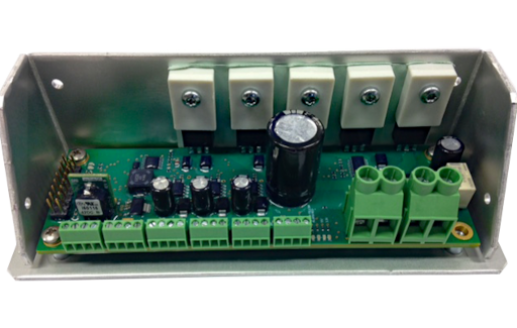

Laird Thermal Systems designs a range of compact thermoelectric coolers, assemblies and temperature controller combinations to achieve precise temperature control inside the chamber as well as rapid cool-down and ramp-up rates. The HiTemp ETX thermoelectric cooler is designed for applications where both heating and cooling is required such as incubators. The SuperCool X Series of thermoelectric cooler assemblies comes in three different models and can be combined with either the SR-54 and PR-59 Temperature Controller. See application note on Heating and Cooling of Incubator Chambers.