Thermal Test Sockets

At the heart of virtually all electronic devices are integrated circuits (IC) or microchips.

Quick Links

To assure their integrity in the field, each chip needs to be thermally tested before assembly into the final product, ensuring proper function and long-life operation. The growing adoption of advanced IC chip testing on the market is driving demands for high-performance, long-life thermal test sockets that are used in the final stage of the semiconductor manufacturing process to weed out inferior chips. Microchip reliability testing can include voltage and environmental testing, such as high temperature burn-in and thermal cycling. One such thermal test is HAST (highly accelerated stress test) that subjects the chip to extreme temperatures and humidity conditions to measure component reliability.

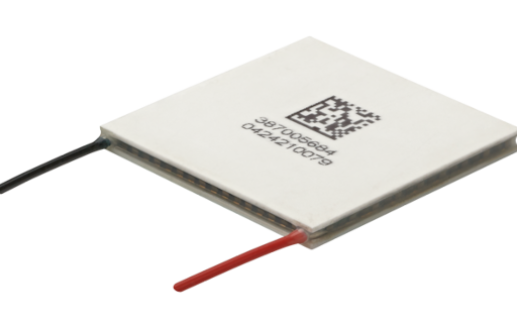

Designers of thermal test sockets must integrate a thermal management solution to provide temperature stabilization in extreme environmental conditions ranging from 0C to 100°C. Thermoelectric coolers provide an optimum solution because they can cycle between heating and cooling modes in the same device and can deliver precise temperature control in a compact form factor.

Thermal cycling exposes thermoelectric coolers to mechanical stresses as the module contracts and expands from repeated cooling and heating cycles. Laird Thermal Systems’ PowerCycling PCX Series features a unique construction that reduce thermal stresses, providing optimal performance and long-life operation. Assembled with next generation materials, the PCX Series achieves faster ramp rates when compared to standard thermoelectric cooler offerings.