HiTemp ETX Series

Security Cameras

CCTV and IP security cameras are being installed in public areas to prevent crime and increase safety while thermal cameras are used for boarder and facility security at night.

Due to sun exposure and heat generated by surrounding components, the operating temperature of security cameras can be as high as 90°C. Lack of airflow, outgassing and thermal noise are other thermal challenges that needs to be taken into consideration when designing cameras for outdoor environments.

Thermoelectric Cooling for Security Cameras

Introduction

The use of outdoor cameras has seen a massive influx with the rise in security monitoring by government and private security agencies. Security cameras are installed with an objective to reduce crime or to improve public safety. CCTV and IP security cameras are installed on every corner in cities, outside hotels and retail stores, all around entertainment venues, stadiums and other commercial and industrial properties. Thermal cameras (infrared sensing) are now often used to improve facility and boarder security at night.

Lidar Sensors

The lasers in Lidar systems, particularly those used in outdoor autonomous applications, require active cooling to achieve maximum resolution in high-temperature environments. As temperatures increase, the wavelength of the laser changes, resulting in increased range error. Maintaining operational temperatures within a Lidar system’s temperature limits ensures peak performance.

Laird Thermal Systems Solutions

High-performance thermoelectric coolers offer a flexible active cooling option for spot cooling of Lidar sensors.

Thermoelectric Cooler Options

Laird Thermal Systems’ offers solid-state thermoelectric coolers with a wide range of sealing and finishing options for maximum performance in your application. In this brochure you will find all available options for our Thermoelectric coolers. All our products are made with high-grade ceramics and semiconductor materials, resulting in Best-in-Class quality performance solutions.

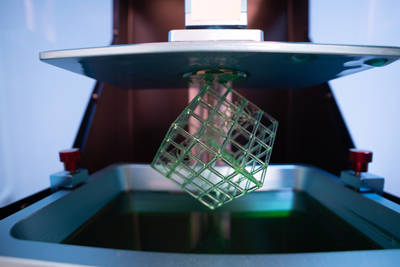

Cooling for Digital Light Processors

The tiny micromirrors are placed on a semiconductor chip, known as a Digital Micromirror Device (DMD). This technology can be found in several industries ranging from Head-up displays and Smart headlights in the automotive market, Smartphones and other display and projection applications to advanced light control in 3D printing.

The tiny micromirrors are placed on a semiconductor chip, known as a Digital Micromirror Device (DMD). This technology can be found in several industries ranging from Head-up displays and Smart headlights in the automotive market, Smartphones and other display and projection applications to advanced light control in 3D printing.

Peltier Cooling for Digital Light Processors

Introduction

Digital light processors employ a laser light source and millions of tiny mirrors to produce vibrant, high-resolution images for a wide variety of industries and applications. It is critical to maintain an optimum operating temperature during use to prevent degradation of the digital light processing technology. Active cooling solutions utilizing thermoelectric coolers can provide digital light processors thermal management in a wide range of high temperature applications.

Peltier Cooling for Machine Vision

Introduction

Machine vision is the replacement of human examination, assessment and decision-making with video hardware and software systems. The technology is often used for vision inspection, quality control, robotics, wire bonding and down-hole applications where machine vision systems obtain data from analyzing images of a specific process or activity.

Thermoelectric Cooling for CMOS Sensors

Introduction

For nearly 50 years CCD (charge-coupled device) sensors and CMOS (complementary metal-oxide semiconductor) sensors have competed on cost and performance in a wide range of digital imaging applications. Peltier coolers (thermoelectric coolers) have cooled both technologies when the requirement demanded high-resolution images. Design engineers opted to use CCD’s for astrophotography, super-resolution microscopy, x-ray crystallography, and spectrophotometric assays. On the other hand, CMOS sensors made inexpensive digital photography a reality.