Introduction

Advances in autonomous technologies, such as smart headlights, autonomous systems for collision avoidance, and infotainment systems, require enhanced thermal protection of critical electronics to ensure optimized performance. These emerging intelligent autonomous systems are increasingly complex while decreasing in size and weight. Packing more functionality into smaller footprints has increased the heat flux density and thermal challenges in autonomous systems. Designing active cooling systems that feature thermoelectric coolers will provide a thermal management solution needed to operate each sensitive device within its temperature range and optimize its performance.

Lighting

Over the past several years, significant advancements have been made to autonomous headlight technology that improves the driving experience. The trend has migrated from incandescent bulbs to high-intensity discharge (HID) lamps to light-emitting diodes (LEDs) and now laser light. This has resulted in improved safety due to the increased illumination allowing drivers to see further, improved color pallet mimicking daylight and ability to angle laser light around corners prior to turning the vehicle.

The development of smart headlight technology is the next phase in autonomous evolution. Smart headlights automatically manage the direction of the high beams on automobiles. For example, they adjust the high beam away from oncoming traffic to avoid blinding the other driver while still illuminating their own lane. Smart headlights direct light, illuminating at an angle in which the car is turning to enhance the driver’s viewable area. The light also travels at farther distances, increasing the reaction time the driver can safely adjust responsiveness.

Smart headlight technology is achieved by lasers and digital light processors. A single laser in each headlight is focused on a grid of tiny mirrors, which are automatically adjusted by an electronic control unit (ECU) to provide optimum lighting of the area in front of the vehicle. Smart headlight technology operates efficiently at temperatures up to 70°C, but the performance degrades as the temperature increases beyond this limit. Autonomous applications may see operating temperatures as high as 110°C due to a combination of external environmental conditions: heat generated by the engine, adjacent electronics, and heat generated by the digital light processor itself.

Laser headlights present a thermal challenge that previously could be solved passively. No matter what the application, critical components have maximum operating temperatures. They are designed, optimized and fabricated in a room temperature environment. However, as the operating temperature of the application increases, the coefficient of thermal expansion (CTE) causes the components to change and minimizes peak performance in temperatures outside of room temperature environments.

The advancement on smart lighting has mostly been with front headlights, as each automotive manufacturer tries new and innovative designs to enhance safety. The technology development efforts on the taillights are lagging, but this could change in the future as more electronics get integrated into a vehicle. Each new design presents its own thermal management challenges.

Imaging Sensors

Many automobiles currently have back-up cameras installed on the rear of the vehicle to assist the driver in safely backing out of a parking spot. Others have imaging sensors inside cameras to provide adaptive speed control when driving on the highway. More recent applications include imaging sensors to check side-on interference as vehicles are passing, or sensors mounted on dashboard to monitor the driver. If this person is nodding off while driving, an alarm will sound to wake them up.

Imaging sensors enable adaptive speed control.

In the future, high end imaging sensors will be used to recognize road signs, street lights, and pedestrians crossing the road to provide collision avoidance for autonomous driving. It is estimated that there will be as many as 12 imaging sensors per vehicle, able to view 360 degrees around the vehicle at all times. The imaging sensor captures an image, which is converted digitally and sent to a computer. One advantage of these sensors is that they capture a high-resolution image in light spectrums that may not provide good visibility to the human eye. Interpretation of the image, such as a STOP or YIELD sign, would not be embedded in the sensor but would be done by a computer with deep machine learning.

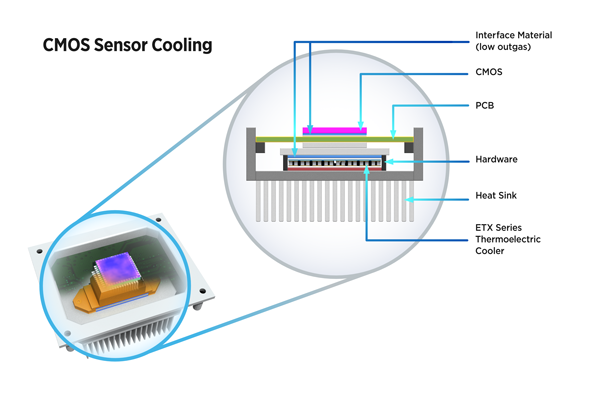

Due to thermal noise, the quality of the image resolution deteriorates as the temperature increases above 60°C. In autonomous applications, the operating temperature can reach up to 90°C, both from the proximity to engine and lack of adequate heat dissipation. Given that the heat rejection path for passive cooling of these devices is not very efficient, a method of active spot cooling will be required to keep the imaging sensors cool while surrounding environment remains hot.

Heads-Up Displays

Heads-up display (HUD) has been used for many years to show the speed a driver is traveling on the windshield. Advancements in infotainment systems have significantly increased the amount of information available to drivers, and in turn the amount of time drivers spend looking down at the center dashboard and console. Global positioning systems (GPS) have almost become standard in automobiles. In the interests of driving safely, OEM’s are looking to keep the driver’s eyes on the road by projecting information from the infotainment system onto the windshield. Additional safety features such as enhancing sign recognition to the windshield, or displaying a pedestrian crossing the street as a marker on the windshield, could be possible to aid in advanced driver-assistance systems (ADAS).

Projecting more information on a transparent windshield requires a larger capacity heads-up display system with more power that generates more heat. Keeping the temperature of the device below its maximum operating temperature presents a need for active spot cooling.

More functionality in infotainment systems have resulted in high capacity head-up displays requiring active cooling solutions.

Lidar

Light detection and ranging (Lidar) is a survey-mapping technology that uses light waves to detect surrounding objects by measuring the time it takes for laser pulses to bounce off objects at a distance. The sensors in the Lidar systems can read a million data points per second, enabling them to build high-quality 3D images of objects around the vehicle. Lidar uses light waves like radar’s use of radio waves or sonar’s use of sound waves. Lasers in Lidar systems require active cooling to deliver high resolution images in elevated temperature environments such as outdoor autonomous applications. As temperatures raise, the laser wavelength changes, resulting in increased range error. Maintaining operational temperatures within a Lidar system’s temperature limits ensures optimum performance.

Lasers in Lidar Systems require active cooling to enable them building

high quality images of surrounding objects.

Challenges

While they may not be commercially available yet, each of these autonomous applications – smart headlights, imaging sensors for autonomous vehicles, heads-up displays for infotainment projection and lidar systems – generate heat that raises the operating temperature above its temperature limit. It prevents the sensitive devices from functioning efficiently, safely and accurately. Some of the heat is generated by the engine and solar load, while additional heat is due to the tight geometric space constraints that confine the devices with limited ability to dissipate heat. It is critical to keep sensitive devices below their maximum operating temperature limits to prevent them from degrading.

If passive cooling is unable to lower the temperature below its operating temp limit, then active spot cooling should be required. Cooling the device below ambient will ensure peak performance is maintained. However, it is important to note active cooling will add to the overall cost of the system and add to the heat rejection path. Using fans for convection to aide in heat dissipation most likely will also be required.

In addition to thermal requirements, environmental considerations also play a role when selecting a cooling solution. For example, outgassing is not acceptable because it can coat the laser or imaging sensor optics, degrading the performance over time. Using thermal materials that do not outgas is vital, as is creating protective exterior mechanisms that prevent moisture, condensation and other outside contaminants from entering into the electronics and damaging them, including active cooling system.

Solutions

A heat sink and interface material alone will only cool to just above ambient. If the heat sink has a high thermal resistance, the hot side temperature will be several degrees above ambient, which is often the case. Spot cooling may be the best possible outcome to keep sensitive electronics below their temperature limit, by incorporating a thermoelectric cooler into the system close to the sensitive electronics that requires cooling. The thermoelectric cooler can create a temperature differential across it, which lowers the temperature differential of the critical device by as much as ~50°C from hot side temperature of heat exchanger. Heat will then need to be routed through a heat rejection mechanism, such as a heat sink and fan, to get the heat transferred into the air environment. It is critical that the hot side heat sink does not saturate otherwise heat will flow back into the device and heat it up. This is where thermoelectric cooler optimization for high coefficient of performance (COP) is critical.

High-temperature thermoelectric coolers provide temperature stabilization

for CMOS sensors used in autonomous applications.

Laird Thermal Systems Thermoelectric Coolers

Each autonomous application system, whether it is smart headlights, imaging sensors, or heads-up displays, needs a good heat rejection mechanism. Laird Thermal Systems has technical applications expertise in thermal management solutions and thermoelectric technology. We can offer standard and custom design solutions for autonomous systems using OptoTEC™ OTX/HTX or HiTemp ETX thermoelectric coolers, offering superior operation at elevated temperatures.

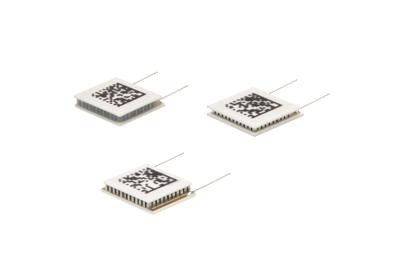

OptoTEC™ OTX/HTX Series

With a footprint smaller than 13X13 mm, the OptoTEC™OTX/HTX Series offers high heat pumping capacity for its size, making it ideal for autonomous applications with tight geometric space constraints. Assembled with next generation material the OTX/HTX thermoelectric coolers boosts cooling capacity over standard product offerings while delivering a higher coefficient of performance.

The OptoTEC Series is offered in two versions; OTX and HTX. While the OptoTEC OTX uses SbSn solder, enabling a maximum operating temperature of 120°C, the OptoTEC HTX thermoelectric cooler uses AuSn solder which allows it to survive in temperatures up to 150°C.

The OptoTEC™ OTX/HTX Series offers high heat pumping capacity in

an extremely small footprint starting from 3 X 4 mm.

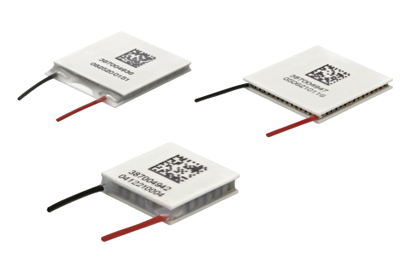

HiTemp ETX Series

Offering a wide range of heat pumping capacities, form factors, and input voltages, the high-performance HiTemp ETX Series product line contains more than 50 models to support a wide range of applications. Compared with standard thermoelectric cooler materials, this model series features a higher thermal insulating barrier creating a maximum temperature differential (ΔT) of 83°C.

The enhanced thermoelectric module construction provides superior protection at elevated temperatures where standard grade thermoelectric coolers fail, without losing cooling performance. The product series maintains a high coefficient of performance (COP) to allow for maximum heat rejection into air environment even with poor heat sinking.

The HiTemp ETX Series is available in more than 50 models

with cooling capacities ranging from 7.7 to 320 Watts.

Our new OptoTEC™ MBX Series is designed for space-constrained applications

Much smaller than the OTX series is the new ultra-compact OptoTEC™ MBX series which meets the needs of next-generation high-temperature applications requiring smaller form factors, lower power consumption, faster response times, and lower cost in high volume. These factors can improve the performance and reliability of the laser diode and enable innovation in optical telecom applications.

Advancements in laser diode technology require higher heat pumping capacities to absorb heat from sensitive optoelectronics and dissipate out through the package. To pump the heat out, thinner profiles and more efficient ultra-small TECs are required to maintain precise wavelength control and temperature stabilization of the laser.

OptoTEC™ MBX Series allows laser diode packages to be designed in smaller form factors without compromising thermal stability. They also respond more quickly to changes in temperature, which is important for applications that require rapid thermal control, such as optical communication systems. Utilizing next-generation thermoelectric materials, advanced manufacturing processes and high-performance ceramic substrates, the MBX Series offers micro footprints as small as 1.6 x 1.6 mm with thicknesses down to 0.65 mm. The packing fraction for thermoelectric materials enables high heat pumping densities up to 43 W/cm2 at lower operating currents than traditional thermoelectric coolers.

Superior heat pumping capacity in a smaller footprint for space-constrained optoelectronic applications

Conclusion

The trend to combine technical sophistication and advanced functionality with miniaturization continues to drive the evolution of active cooling solutions – particularly in high-temperature environments like autonomous applications. Emerging autonomous system technologies, like smart headlight lights, imaging sensors and heads-up display units, require active cooling to ensure peak performance is maintained over the life of the vehicle. Heat fluctuation in these critical systems can cause degradation in performance, and even system failure. Designing high-performance thermoelectric coolers such as the HiTemp ETX or OptoTEC OTX/HTX Series into the system protects the sensitive electronics and optimizes performance.

More information on the OptoTEC OTX/HTX Series can be found by visiting

https://www.lairdthermal.com/products/thermoelectric-cooler-modules/peltier-optotec-otx-htx-series

More information on the HiTemp ETX Series can be found by visiting

https://www.lairdthermal.com/products/thermoelectric-cooler-modules/peltier-hitemp-etx-series

More information on the OptoTEC MBX Series can be found by visiting

https://lairdthermal.com/products/thermoelectric-cooler-modules/micro-MBX-series