Introduction

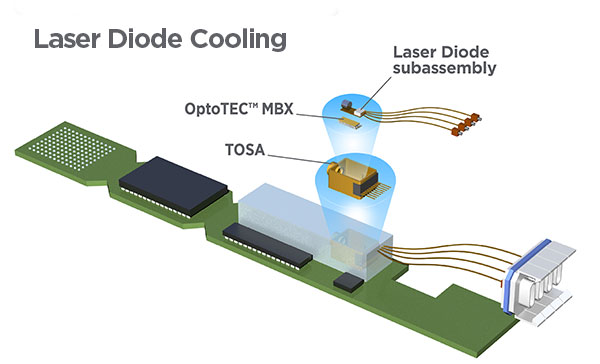

Fiber optic technology has essentially replaced copper wire in datacom and telecommunication industries. Emerging applications, including artificial intelligence and machine learning, require higher data transfer speeds and bandwidth across significant distances all at a lower cost. In many applications, temperature stabilization improves the performance and longevity of critical optoelectronic components vital in fiber optic systems. In this application note, we will discuss laser diodes commonly used in telecom applications, and how ultra-small thermoelectric coolers (TECs) can remove the heat generated in the laser diode package to optimize overall performance.

Micro thermoelectric coolers remove the heat generated

in the laser diode package to optimize overall performance

Technology Snapshot

Laser diodes are an important component in the development and expansion of fiber optic networks. In fiber optic communication systems, laser diodes are used as a light source to transmit data over fiber optic cables. The beam of light produced by the laser diode can be easily coupled into a fiber optic cable, where it is transmitted over long distances with minimal attenuation or signal loss. Laser diodes are the preferred technology for optoelectronics applications due to their small size, low power consumption, and high-data speed capability. A laser diode is a type of laser made from a semiconductor material, such as gallium arsenide (GaAs) or indium gallium arsenide (InGaAs). Unlike other types of lasers that use a gas or liquid as the active medium, a laser diode uses a solid-state material to generate light.

Application Overview

Laser diodes are used in a wide range of applications including telecom, datacom, LIDAR, 3D sensing, healthcare, additive manufacturing, facial recognition and more. According to Mordor Intelligence, the global laser diode market was valued at USD 8.84 billion in 2020 and is expected to reach USD 16.25 billion by 2026, registering a CAGR of 11.2%, between 2021 - 2026. Some common uses of laser diodes in telecom applications include:

- Pluggable optical transceivers: typically mounted inside the transceiver module, laser diodes emit a beam of light at a specific wavelength that is coupled into a fiber optic cable to provide high-speed data transmission over long distances

- Wavelength division multiplexing (WDM) systems: laser diodes are used to multiplex multiple optical signals onto a single fiber, allowing for the efficient use of fiber optic bandwidth

- Optical amplifiers: laser diodes are used to increase the signal strength of optical signals for longer-distance transmission

Types of Laser Diodes Used in Telecom Applications

There are several types of laser diodes commonly used in telecom applications. The choice of laser diode depends on the specific requirements of the telecom application, including distance, data rate, available bandwidth, power consumption, wavelength and the trade-offs between performance, cost, and reliability. Below are examples of laser diodes used in telecom applications:

- Fabry-Perot (FP) laser diodes: commonly used in fiber-optic transmission systems as the light source for modulated optical signals

- Distributed feedback (DFB) laser diodes: use a grating structure that acts as a feedback mechanism to control the wavelength of the laser light. DFB laser diodes are used in applications that require a narrow and stable laser wavelength, such as dense wavelength division multiplexing (DWDM) systems in optical communication networks

- Vertical cavity surface emitting lasers (VCSELs): type of surface-emitting laser diodes (SELs) that emit light vertically from the surface of the diode. VCSELs are used in applications that require low-cost, high-speed, and high-efficiency lasers, such as optical communication systems, data center interconnects, and fiber-optic sensing

- Coherent laser diodes: produce a narrow and stable linewidth, making them suitable for coherent optical communication systems used in machine learning and big data applications

- Pump lasers: used to pump optical amplifiers, such as erbium-doped fiber amplifiers, to amplify an optical signal; sea fiber cabling and relay stations in fiber optic communications use laser pumps to boost signals

Laser Diode Packaging

Laser diode packages are designed to provide hermetic sealing, passive cooling, and optical and electrical connections for the laser diode. The specific package chosen depends on the telecom application requirements such as function, performance, environmental conditions, and the available space. A few examples of commonly used diode packages for telecom applications include:

- Butterfly Package: named after its distinctive shape, which resembles a butterfly, the compact and low-cost package typically consists of a metal housing that provides mechanical support and cooling for the laser diode

- TO Can Package: a cylindrical package that provides good thermal performance and a high level of mechanical stability

- TOSA Package: a transmitter optical sub-assembly is used to convert signal into an optical signal coupled into an optical fiber cable

- ROSA Package: a receiver optical sub-assembly receives an optical signal from a fiber and converts it back into an electrical signal

- BOSA Package: a bi-directional optical sub-assembly consists of both a TOSA and ROSA

- Pigtailed Package: provides a simple and straightforward optical connection, the package consists of a laser diode that is mounted onto a package with an optical fiber pigtailed

- Multi-Source Agreement (MSA) Package: designed to provide compatibility between different components and systems, making it easier to integrate laser diodes into a telecom network

Laser Diode Performance

The performance of a laser diode is influenced by many factors, including temperature, current, and optical power. Changes in temperature can cause changes in the electrical and optical properties of the laser diode, which can affect its performance. Operating at elevated temperatures continuously can also shorten the life span of the device.

The operating temperature of a laser diode varies depending on several factors, such as the type of laser diode and package, the power of the laser diode, and the operating conditions. Standard laser diodes designed for telecom applications operate within a specific temperature range between -10C and 85C, although laser diodes in new optical devices can operate at higher temperatures. Emerging telecom applications pursuing more than 400 Gb/s feature new optical devices and an expanded maximum temperature range.

At temperatures outside the maximum operating range, the performance of a laser diode can degrade due to increased thermal resistance and reduced current gain. This can result in decreased laser output power and increased threshold current. High temperatures can also shift the wavelength of a laser diode, impacting its performance and reliability. The shift in wavelength is caused by changes in the refractive index of the semiconductor material used in the laser diode. In some cases, a severe shift in wavelength can lead to significant crosstalk (interference), or even failure of the laser diode. For example, a DFB laser diode used in an optical communication application typically emits light at a wavelength of around 1260-1650 nm. An increase in temperature causes a shift in the peak wavelength (toward the long wavelength) of around 0.1 nm/°C.

At lower temperatures, the performance of a laser diode can improve due to reduced thermal resistance and increased current gain. This can result in increased laser output power and reduced threshold current. However, low temperatures outside the minimum operating range can also cause reduced photon life, increased recombination losses, and increased internal losses, which can offset the benefits of reduced thermal resistance.

Another problem attributed to fluctuations in temperature is that of crosstalk. This can be seen in communication links that require high bandwidth and long distances. Hyperscale data centers are an example of this with optical transceivers that use wavelength-division multiplexing to increase data throughput in optic fibers by combining multiple data streams in parallel. (IEEE Transactions on Components, Packaging and Manufacturing Technology, August 2022)

It is important to maintain a stable temperature of a laser diode to maintain a consistent wavelength, eliminate crosstalk and ensure reliable performance. This can be achieved through temperature control systems that use thermoelectric cooling.

Laser Diode Cooling Challenges

Thermal management of laser diodes is more challenging than ever. More data is being transferred at higher speeds, power densities continue to increase, and product form factors continue to shrink. This inherently results in higher heat flux densities. The need for effective and efficient thermal management solutions is imperative to ensure the proper performance and longevity of laser diodes.

Cooling Methods

There are several methods used to regulate the temperature of a laser diode:

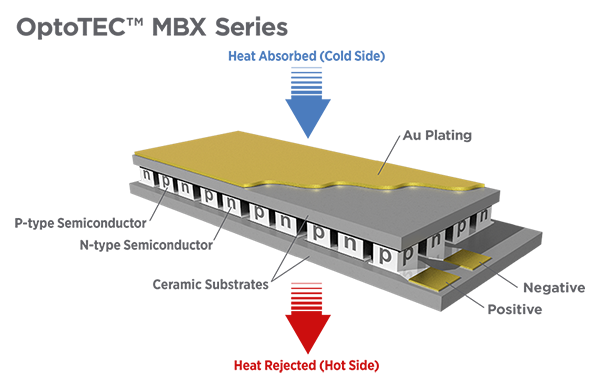

- Active cooling: more often used in datacom at the server or switch level, active cooling involves the use of cooling fans, heat sinks, forced liquid or thermoelectric coolers to remove heat from the laser diode package. This is typically done by attaching the laser diode to a heat sink and using a fan to dissipate the heat generated by the laser diode into the surrounding air. A thermoelectric cooler (TEC) is a device that can cool or heat a small area by converting electrical energy into thermal energy. The thermoelectric cooler can be used to cool the laser diode by removing heat from the laser diode and dissipating it into the optical package, which then dissipates heat to the surrounding environment

- Passive cooling: relies on natural convection or thermal conduction to remove heat from the laser diode. For example, a heat sink can be attached to the laser diode to absorb and dissipate the heat generated by the laser diode

- Temperature control circuits: electronic circuits used to control the temperature of the laser diode by adjusting the current and/or voltage supplied to the laser diode. The temperature control circuit can be designed to maintain the laser diode temperature at a constant value or to vary the temperature based on the desired operating conditions

Why Ultra-small or Micro TECs?

Advancements in laser diode technology also require advancements in thermal management solutions. Laser diodes generate more heat as data throughput speeds increase and the distance between connection points increases. As a result, laser diode packages require higher heat pumping capacity to move heat away from sensitive electronics and out of the package. To pump the heat out, micro TECs with higher packing fractions and thinner profiles are required to improve efficiency and maintain precise wavelength control and temperature stabilization.

New thermoelectric materials and high-precision manufacturing processes have enabled the development of micro TECs with lower profiles. This allows laser diodes to be made in smaller form factors without compromising thermal stability. They also respond more efficiently to changes in temperature, which is important for applications that require an efficient thermal control response, such as in optical communication systems. Higher efficiency can improve the laser diode performance and reliability enabling higher data transmission rates. In addition, micro TECs can be manufactured inexpensively with high throughput, which can help reduce the overall cost of the laser diode system.

The new OptoTEC™ MBX series from Laird Thermal Solutions is ideal for laser diodes temperature stabilization. Smaller than the OTX series, the ultra-miniature MBX series meets the requirements of modern laser diode applications including smaller size, lower power consumption, higher reliability, and lower cost in mass production. These factors can improve the performance and extend the reliability of the laser diode to enable innovation in next-generation telecom applications.

Implementation

Temperature stabilization is a key challenge in the field. For example, the typical operating temperature range for a laser diode is between 25°C and 85°C. If housed in an 85°C environment, then cooled to 25°C, the device will almost reach maximum performance at a 60°C temperature differential with minimal heat pumping capacity. While these applications need cooling, the heat removal required must be done efficiently through low thermal resistance heat conduction paths in the package. The following design considerations below should be evaluated to remove heat efficiently:

- Optimized TEC Design: application requirements need to be thoroughly understood at the desired operating point. The geometry factor and number of couples can be optimized to match heat removal requirements from the laser diode plus passive heat losses. Thermal resistances of the hot and cold side need to be accounted for as they will reduce temperature differential across the thermoelectric cooler quite a bit

- Package Design: the least expensive package in the smallest form factor is often chosen. However, the package is the key heat dissipation mechanism, and may not have the best thermal conductivity. As the form factor of the package shrinks, the heat flux density increases and poor heat dissipation can lead to thermal runaway. This can be avoided by sizing the package and thermal conductivity of the material to accommodate total heat rejection required from the TEC and laser diode

- Interface between TEC and package: the solderability of the TEC to the package is critical to assure proper heat rejection from the TEC. Poor solder adhesion leads to solder voiding and this increases the hot side thermal resistance. Proper plating materials need to be specified on ceramic substrate surfaces of the TEC in combination with optimal solder to assure a thin bond layer is achieved with minimal solder voiding. This will have maximum impact by increasing efficiency of the TEC in operation

- Parasitic Losses: passive heat losses can occur from a thermal short between the hot and cold side of the TEC. Most packages are hermetically sealed in vacuum or gas, so this minimizes thermal losses from passive heat in the surrounding environment. However, lead attachments to the TEC and optical devices on the cold side substrate of the TEC are susceptible to heat transfer from the hot side. This will cause the TEC to consume more input power to achieve the same cooling power required. It is ideal to design the TEC to operate at a lower current since this will reduce the gauge thickness of the lead wire and reduce heat transfer from the lead wires

Once main design variables have been determined, the TEC is controlled by a temperature control circuit, which adjusts the current supplied to the TEC to maintain the laser diode at the desired control temperature. Other variables to consider are substrate materials and solder construction of the TEC. Materials exist with higher thermal conductivity and solder adhesion, which boost performance, heat spreading and reliability, but they must be weighed against cost targets of the end user application. Most applications cannot support higher material costs in high volume.

Conclusion

Optical communication has been one of the driving forces in developing laser diode technology. Laser diodes play an important role in ensuring the reliability and stability of these systems. However, temperature fluctuations can affect the performance of a laser diode, and it is important to maintain a stable temperature to ensure consistent and reliable performance. High temperatures can degrade performance, while lower temperatures can improve performance, but also have potential drawbacks including reduced photon life. By employing micro TECs inside laser diode packages, laser diode performance and operating lifetime can be optimized. TECs are an ideal technology for cooling laser diodes because they provide high cooling power, fast response time, compact size, energy efficiency, low energy consumption and ease of temperature control.

For more information on the OptoTEC™ MBX Series CLICK HERE