Introduction

Rheometers are scientific instruments used for studying the stress-strain relationship of polymers, fluids, and other soft materials to understand their flow/deformation properties. Rheometers are applied in a wide range of applications, such as in the development of new materials, quality control, and process optimization. Any rheometer that operates at elevated temperatures or measures temperature-dependent material properties requires a cooling system to maintain a precise temperature during testing. The specific type of cooling system used will depend on the requirements of the test and the properties of the sample.

Types of Rheometers

Rheometers work by applying controlled deformation or stress to a material and measuring the resulting response. The deformation can be applied in various ways, such as through rotational or oscillatory motion, shear flow, compression, or extension. The resulting response can be measured in terms of parameters such as viscosity, elasticity, shear modulus, yield stress, and other rheological properties.

Parallel Plate Rheometer for liquids over a large temperature range

There are several types of rheometers available, each designed for specific applications and material properties. Some common types of rheometers include:

- Rotational: measure the torque and angular velocity of a sample while it is rotated or sheared. Rotational rheometers are versatile and can be used to test a wide range of materials, including liquids, pastes, and gels.

- Oscillatory: apply small, sinusoidal deformations to a sample and measure the resulting stress and strain. Oscillatory rheometers are particularly useful for studying the viscoelastic properties of materials, including their storage and loss moduli.

- Capillary: measure the flow properties of materials as they pass through a narrow, cylindrical tube. Capillary rheometers are commonly used to study the flow behavior of polymers, particularly in extrusion and injection molding processes.

- Extensional: measure the extensional properties of materials, including their elongational viscosity and extensional stress. Extensional rheometers are used in applications such as polymer processing, fiber spinning, and coating.

- Cone-and-plate: consists of a rotating cone that is pressed against a stationary plate, creating a shear flow in the sample. Cone-and-plate rheometers are commonly used to study the rheological properties of liquids and semi-solid materials.

- Micro: designed for measuring the rheological properties of small samples, such as biological tissues or microfluidic systems. Micro-rheometers can be based on any of the above principles but are adapted for smaller-scale samples.

Rheometer for characterization of cell powder

Application Requirements

Rheometers are used in a wide range of applications to study the flow and deformation properties of materials. A rheometer may require a cooling system to maintain the sample at a constant temperature during testing. This is because many materials exhibit temperature-dependent rheological properties, meaning their flow and deformation behavior can change significantly with temperature. Therefore, it is important to control and maintain the sample temperature to obtain accurate and repeatable measurements.

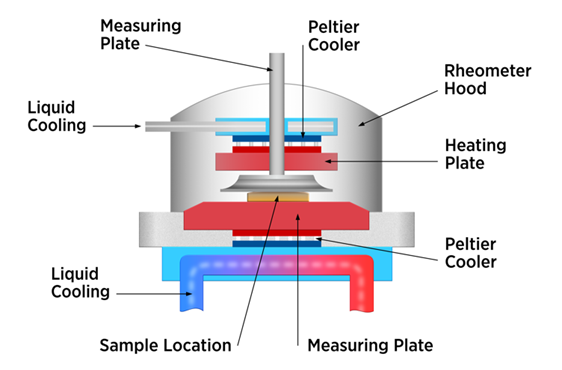

A cooling system can help to maintain the sample at a constant temperature during testing by circulating a temperature-controlled fluid or refrigerant through the sample holder or the measuring geometry. This can be achieved using a variety of cooling mechanisms, such as a thermoelectric cooler, a Peltier element, or a refrigeration unit. The cooling system can be designed to provide precise temperature control, typically within tenths of a degree Celsius, to ensure accurate and reproducible results.

For example, some materials such as polymers, may have a glass transition temperature (Tg) below room temperature, and their properties can change rapidly as the temperature increases above Tg. Tg is the temperature range where a polymer substrate changes from a rigid glassy material to a soft material (not melted). This is a reversible transition when the polymer is heated or cooled in a particular temperature range. In this case, maintaining a constant temperature during testing is crucial to obtaining accurate measurements of the material's rheological properties.

Common rheometer applications include:

- Polymer processing: rheometers are used to study the flow and deformation behavior of polymers during processing, such as extrusion, injection molding, and blow molding. In these applications, rheometers are used to test the rheological properties of the polymer melt or solution point at elevated temperatures. The cooling requirements for these tests will depend on the processing conditions of the specific material but may require thermal stability at elevated temperatures between 100°C to 300°C or higher.

- Food science: rheometers are used to study food materials such as gels, emulsions, and suspensions. In these applications, the samples are often temperature-sensitive and may need to be tested at or slightly below room temperature. The cooling requirements for these tests may range from a few degrees below room temperature to slightly above.

- Biomedical research: rheometers are used to analyze the mechanical properties of biological tissues, such as cartilage, muscle, and bone. In these applications, the samples are often delicate and may be temperature sensitive. The cooling requirements for these tests may range from slightly below room temperature to slightly above.

- Petroleum industry: rheometers are used to research crude oil, drilling fluids, and other petroleum products. In these applications, the samples may need to be tested at elevated temperatures, ranging from around 50°C to 200°C or higher, depending on the specific application.

The temperature to which a rheometer needs to be thermally stabilized depends on the material being tested and the specific requirements of the test. The rheometer's cooling system should be able to maintain a stable and accurate temperature throughout the testing process, within the temperature range required for the specific material and application.

Types of Cooling Sytems

Rheometer designs can use various types of cooling systems to maintain the temperature of the sample during testing. The choice of cooling system depends on the specific requirements of the rheological test and the sample being tested. Some common types of cooling systems used in rheometers include:

- Peltier element cooling: also known as thermoelectric coolers, these semiconductor devices can transfer heat from one side to the other when an electric current is applied. They are compact and efficient and can be used for cooling small sample volumes

- Refrigeration-based cooling: refrigeration units (recirculating chillers) are typically used for larger sample volumes and provide precise temperature control

- The combination of Peltier and Refrigeration-based cooling allows the performance range of the thermoelectric cooling to be extended by exposing the heat sink side of the semiconductor to temperatures well below or above ambient conditions.

- Liquid nitrogen cooling: can be used as a cooling medium to rapidly cool the sample to very low temperatures. This is typically used for samples that require extremely low temperatures, such as those used in cryogenic testing

Additionally, when recirculating chillers are used with Peltier elements integrated into the rheometer instrument, an even broader range of temperature control can be achieved. This enables rheometers to test a wider variety of materials while ensuring accurate results.

Plate-Plate Geometry

Recirculating Liquid Cooling

Recirculating chillers, like the Nextreme™ Chiller Series from Laird Thermal Systems, are ideal for rheometer applications because they provide fast, efficient and precise cooling to well below ambient temperatures. Offering high heat pumping capacity and low-noise operation in a smaller and lighter package, Nextreme recirculating chillers feature either compressor- or thermoelectric-based technology as the cooling mechanism. The innovative chillers can cool up to 4900W and maintain a temperature range from -10°C to 40°C.

With multiple series and models developed to future-proof Rheometer designs and other lab equipment, these recirculating chillers offer standard features and options allowing for application-specific configurations.

The Nextreme Recirculating Chiller Series can lower energy consumption by up to 50% compared to conventional compressor-based systems. High-quality components, including variable speed motors for the compressor and condensing fan, provide lower noise operation and a higher coefficient of performance compared to competing models.

The semi-closed fluid system features a pressure-vacuum reservoir cap to prevent evaporative losses, the introduction of bacteria, and fluid drain-back that eliminates the need for additional hardware. With the reservoir design, less time is required to maintain system operation and uptime, and a higher fluid quality level allows for longer life of critical components like the pump, heat exchangers, and sensors.

New Refrigerants

Today, there is a push to develop refrigerants that have a low global warming potential (GWP). Government and environmental regulations have helped phase out many harmful refrigerants in lieu of more environmentally friendly alternatives. Some of these refrigerants include hydrofluoroolefins (HFOs), natural refrigerants (ammonia and carbon dioxide), and hydrocarbons (isobutane and propane).

When selecting a recirculating chiller for a rheometer, it is important to carefully evaluate the options and select a system that meets the needs of the application, while also complying with relevant government and environmental regulations. The specific type of refrigerant used will depend on the specific needs and requirements of the rheometer and the materials being tested.

Adapting to ever-changing government regulations, the Nextreme Chiller uses a more environmentally friendly R513A refrigerant with half the Global Warming Potential (GWP) compared to traditional hydrofluorocarbons (HFC) refrigerants. The platform also meets UL61010-1 or IEC 61010-1 lab safety standards.

Conclusion

Rheometer temperature control requirements hinge on the material being tested and the specific rheological properties that need to be measured. Materials have different temperature-dependent properties, so the cooling requirements will vary depending on the material being tested. Thus, the choice of cooling system will depend on factors such as the required temperature range, the volume of the sample, and the specific rheological test being performed. Recirculating chillers that have environmental benefits are becoming the preferred method for cooling medium to large volume rheometers. Some rheometers may use a combination of cooling systems, such as a recirculating chiller and thermoelectric component, to provide greater flexibility and control over the temperature of the sample. The Nextreme Recirculating Chillers Platform provides more consistent and precise temperature control compared to other cooling solutions, making it an ideal choice for a large number of rheometer applications.

Inquire about our Nextreme™ Series, Recirculating Chillers Solution for your application.