Industrial Laser

There are many applications of industrial lasers. Whether used for cutting, welding, micro-machining, additive manufacturing or drilling, industrial lasers generate a significant amount of heat that can affect accuracy and repeatability of the system.

Quick Links

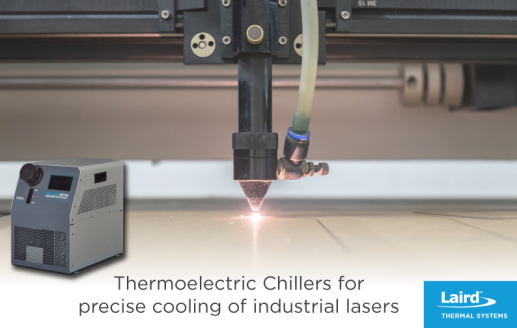

There are many applications of industrial lasers. Whether used for cutting, welding, micro-machining, additive manufacturing or drilling, industrial lasers generate a significant amount of heat that can affect accuracy and repeatability of the system. Efficiently cooling lasers ensures proper, long-term performance of the laser. Compressor-based refrigeration systems have long been used to cool laser systems, while thermoelectric-based chillers or coolers offer spot cooling for low power lasers and optical components. Larger systems greater than 500W typically require an external compressor-based chiller while systems smaller than 500W use a thermoelectric based chiller or thermoelectric coolers.

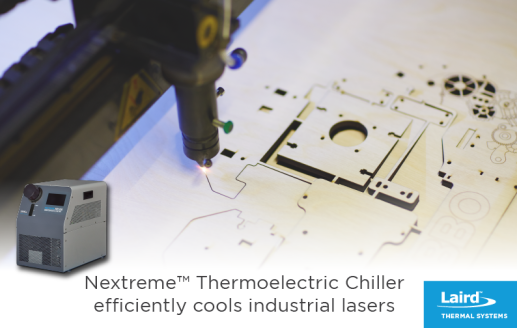

Nextreme™ Recirculating Chillers

Compressor-based refrigeration systems are traditionally used in industrial laser applications because of their high coefficient of performance (COP). Laird Thermal Systems’ Nextreme™ Recirculating Chiller Series delivers reliable and precise temperature control for industrial laser systems. The chiller utilizes high-performance variable speed motors for low noise operation and reduces energy consumption by up to 50% compared to conventional compressor-based systems.

Find Nextreme™ Chiller Series or see application notes:

- Recirculating Chillers for Industrial Lasers

- Thermoelectric Chillers for Low-Power Lasers

- OEM Perspectives: Recirculating Chillers for Industrial Lasers

- OEM Perspectives: Thermoelectric Chillers for Low-Power Lasers

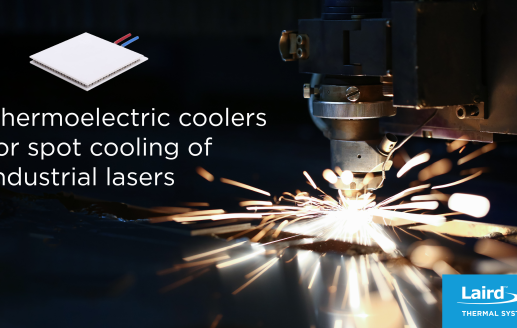

UltraTEC™ UTX Thermoelectric Coolers

Laird Thermal Systems UltraTEC UTX Series is a high performance thermoelectric cooler used for applications in industrial lasers and optics where high heat pumping capacity is required in a small surface area. The UltraTEC UTX Series features a higher thermal insulating barrier that creates a greater temperature differential compared to standard thermoelectric coolers. Assembled with advanced thermoelectric materials, the UTX Series of thermoelectric coolers offers a 10% boost in heat pumping capacity.

Find UltraTEC UTX Series or see application note on Spot Cooling for Industrial Lasers & Optics