RT Series Regenerative Turbine Refrigerant Cooling Pumps

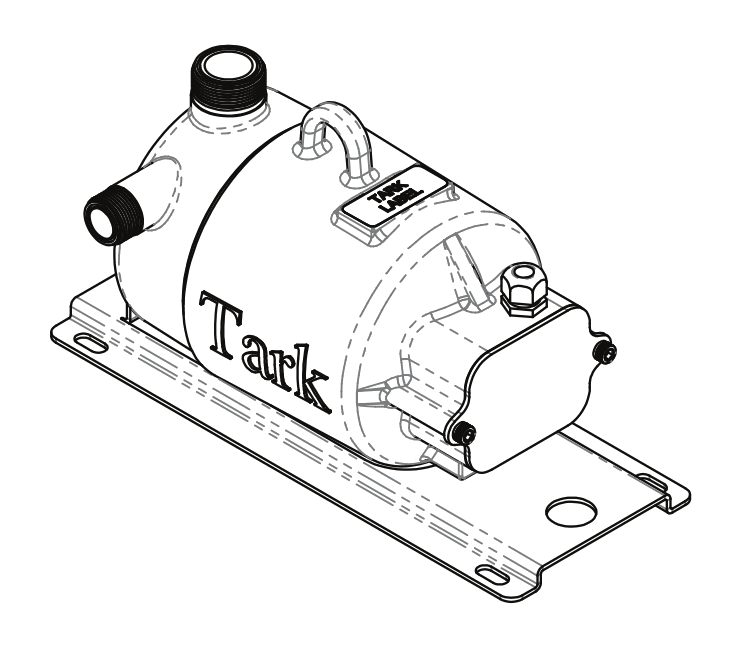

RT Series Regenerative Turbine Cooling Pumps are precision engineered for pumping liquid refrigerant through a cooling system loop, directly to blade servers and chips, ensuring heat removal. Delivering high-efficiency, extended life, and quiet operation – this hermetically sealed regenerative turbine pump is designed with high-pressure and low flow rates in mind, making it ideal for high-density data center racks.

RT Series Regenerative Cooling Pumps Benefits

- High pressure pump with low energy intake

- 600 PSI operating pressure

- 2,500 PSI construction pressure - Power Supply - 3 Phase, 400/460V AC, 50/60 Hz

- Cooling capabilities

- Flow Rate 0-36 GMP

- Quality material selection to ensure longevity and no leaching

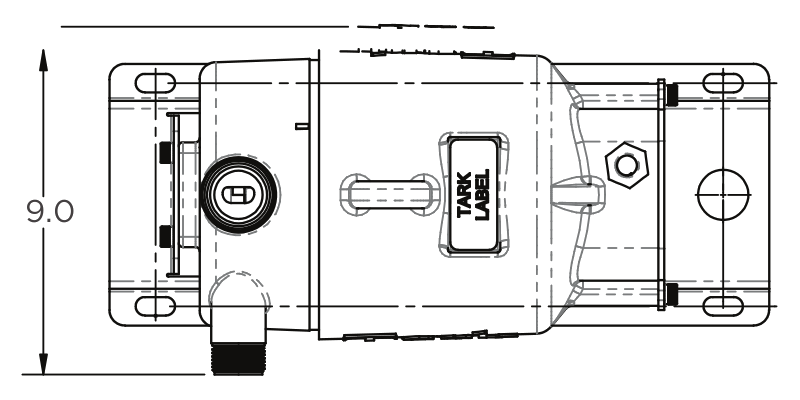

- Compact footprint to minimize space claim

- Precise operating controls

- Low decibel operation

The RT Series Advantage

- Tailor made for high-density cooling and immersion applications

- Designed for HPC cooling

- Reduced footprint maximizing available rack space

- Life expectancy optimized for 80,000 hours

- Increased durability via optimized flow path and minimized wetted material wear

- Low energy consumption and power draw

- Precision motor controls that optimize cooling performance

- Low maintenance design w/ easy service

- accessibility

High Density CDUs | Immersion Cooling |  High Performance Computing Environments |

RT Series Regenerative Cooling Pump Specifications

PERFORMANCE

| RT Series | |||

|---|---|---|---|

| Input Voltage | 400 VAC 50 Hz | 460 VAC 60 Hz | 3080 VAC 60 Hz |

| Power | 5HP (3.7Kw) | 5HP (3.7Kw) | COMING IN 2025 |

| Variable Speed (RPM) | 3000 | 3450 | |

| Flow Rate Range (GPM) | 0 - 30 | 0 - 36 | |

| Pressure Range (PSI) | 0 - 150 | 0 - 150 | |

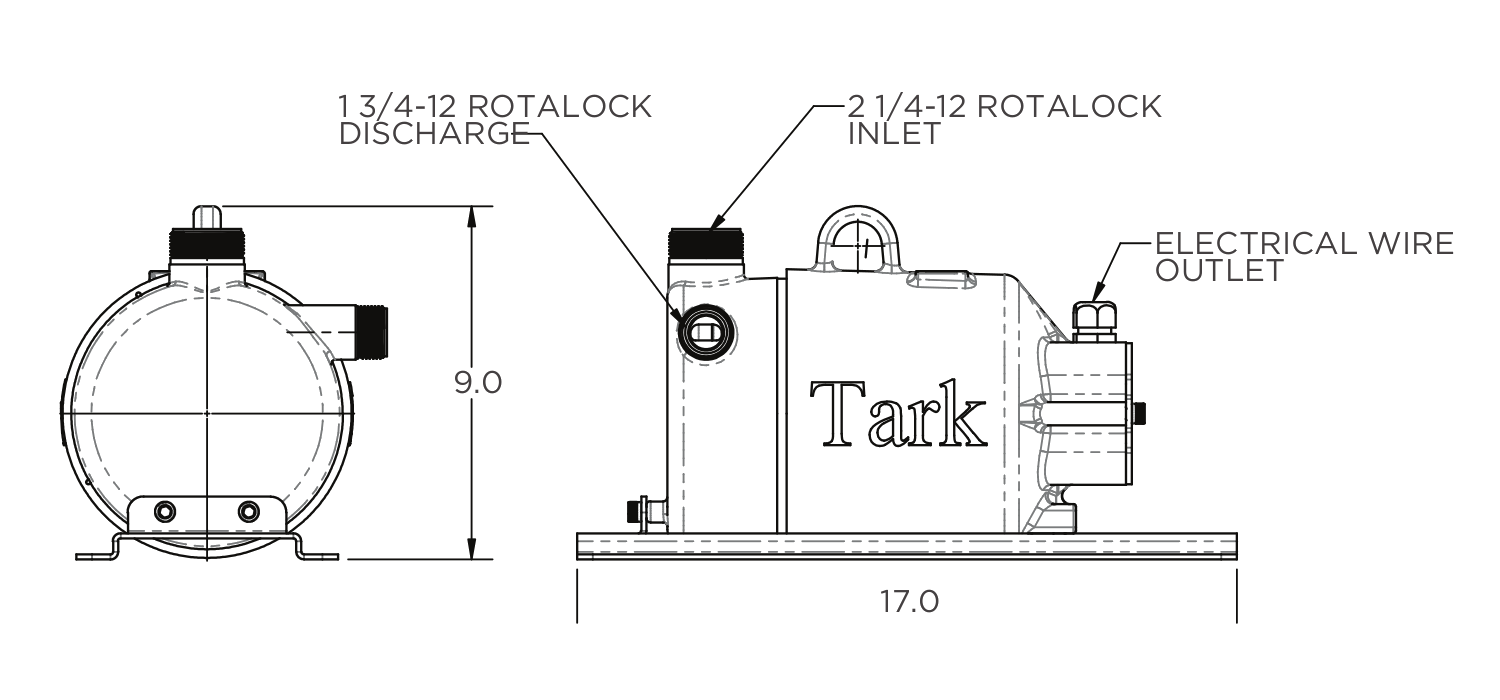

| Inlet* | 2 ¼” – 12 Rotalock | 2 ¼” – 12 Rotalock | |

| Outlet* | 1 ¾” – 12 Rotalock | 1 ¾” – 12 Rotalock | |

| Reliability | 10 Year Life | ||

| Max Temperature (°C) | 60 | ||

*Customization available as well as multiple outlet configurations upon request

Wetted Material

| SHAFT | HOUSING | BEARINGS | IMPELLER | CASING |

|---|---|---|---|---|

| ASTM A108 4140 | 304SS | Hybrid Ceramic | Brass | Brass |

MATERIAL COMPATIBILITY

R134a / R515B / R471A / R1234ze (E) / R1234yf