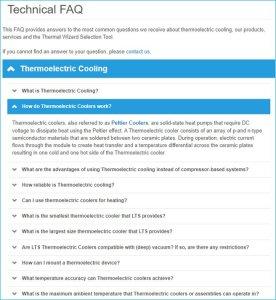

技術的なよくある質問

この FAQ では、熱電冷却、当社の製品、サービス、および Thermal Wizard Selection Tool に関して最もよく寄せられる質問への回答を提供します。英語でのみ利用可能です。

クイックリンク

Thermoelectric cooling is a way to pump heat from one side of a device to the other by applying voltage between two electrodes connected to a sample of semiconductor material. The temperature differential that appears, which is known as the Peltier Effect, can be used for cooling, heating and precise temperature control for various applications.

Thermoelectric coolers, also referred to as Peltier Coolers, are solid-state heat pumps that require DC voltage to dissipate heat using the Peltier effect. A Thermoelectric cooler consists of an array of p-and n-type semiconductor materials that are soldered between two ceramic plates. During operation, electric current flows through the module to create heat transfer and a temperature differential across the ceramic plates resulting in one cold and one hot side of the Thermoelectric cooler.

- Thermoelectric coolers have no moving parts; their solid-state construction results in higher reliability, lower maintenance and lower overall operating costs.

- Solid-state construction also allows Thermoelectric coolers to be mounted in any orientation.

- A compact form factor makes them suitable for applications where size constraints exist.

- Thermoelectric coolers can cool well below ambient. By using a multistage thermoelectric cooler in a vacuum environment, the device can reach a temperature of -100°C.

- Thermoelectric coolers can achieve precise temperature control (up to ± 0.01°C under steady state) because they are able to heat and cool by simply reversing polarity, which changes direction of the heat transfer. This ability also makes them suitable for applications requiring both cooling and heating.

- Thermoelectric coolers are also environmentally friendly because they do not use hazardous CFC’s or produce electrical noise.

Thermoelectric coolers are highly reliable because they have a solid-state construction with no moving parts. They are also known for having a high mean time between failures (MTBFs). It is difficult to estimate the lifetime of a thermoelectric cooler, due to the variables in application conditions such as changes to heat load, on/off cycling, heat or cooling, drive circuit and system design with protection against condensation. All variables can influence the product’s lifetime.

However, for demanding applications such as modern diagnostic, which require high rates of thermal cycling, the PowerCycling PCX Series thermoelectric coolers have been tested to withstand rigorous cycle testing based on latest PCR industry test protocol without degradation in performance.

However, for demanding applications such as modern diagnostic, which require high rates of thermal cycling, the PowerCycling PCX Series thermoelectric coolers have been tested to withstand rigorous cycle testing based on latest PCR industry test protocol without degradation in performance.

Yes, thermoelectric coolers can be used for heating in certain applications. In fact, a thermoelectric cooler can be more effective than a resistive heater since it can utilize heat from the ambient temperature in addition to the heat generated from the cooler itself.

The OptoTEC™ OTX/HTX Series is our smallest thermoelectric module starting at 3.3 x 4.9 x 2.6-mm (LxWxH) with a cooling capacity of 0.4 Watts.

Our largest thermoelectric module is the UltraTEC™ UTX Series, 55 x 55 x 3.9 mm (LxWxH).

Yes, thermoelectric coolers are compatible with vacuum since they have no organics on any material that would outgas. The only restriction would be to not use PVC insulated leads, because PVC out-gasses. Teflon leads and un-insulated wire leads would be preferred.

There are three different ways of mounting thermoelectric coolers; soldering, compression with mechanical hardware or epoxy. The most suitable method depends on the application and the size of the footprint. Thermoelectric coolers can be mounted in any orientation. Read the TEM Handbook manual for more information.

Thermoelectric coolers have a very high temperature accuracy since the applied current is relative to the cooling it generates. Temperature control accuracy up to ±0.01°C can be achieved under steady state condition with a temperature controller of same accuracy to this tolerance.

The maximum operating temperature of standard thermoelectric coolers is 80⁰C. For higher temperatures, our HiTemp ETX Series thermoelectric cooler offer cooling for applications with ambient temperatures up to 150°C. For thermoelectric cooler assemblies, the Outdoor Cooler Series has the widest capacity range with an operational capacity from -40°C to +55°C ambient. The SuperCool Series thermoelectric cooler assembly can withstand the highest temperature of 60°C.

Yes. The Multistage MS Series is able to reach colder temperatures than single stage thermoelectric coolers. Laird Thermal Systems offers two, three, four and five stage thermoelectric coolers that achieve temperature differentials of up to 131°C in a vacuum. The drawback is efficiency will go down with each stage.

Thermoelectric cooling systems are most beneficial in applications with

- Tight space constraints

- Low heat load capacities, typically less than < 400W

- Control temperatures below ambient

- Precise temperature control

- Heating and cooling