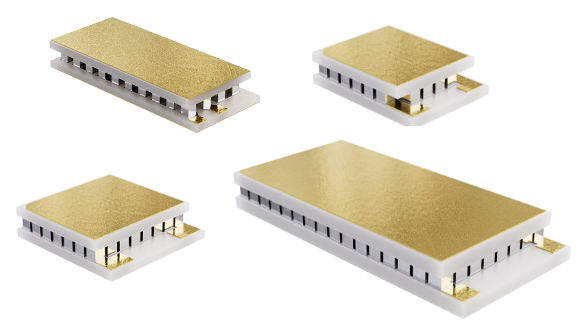

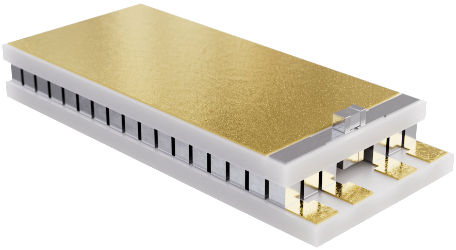

OptoTEC™ MBX Series

The MBX Series of micro thermoelectric coolers support high-temperature applications with compact geometric space constraints. MBX delivers precise temperature stabilization under changing environmental conditions.

クイックリンク

The MBX Series offers micro footprints as small as 1.6 x 1.6mm with thicknesses down to 0.65mm. The packing fraction for thermoelectric materials enables high heat pumping densities up to 43 W/cm2 at lower operating currents than traditional thermoelectric coolers.

The compact MBX Series is designed for use in

- LiDAR systems for autonomous vehicles

- Pluggable optical transceivers for telecom

- Indium Phosphide VCSELs used in various high-performance applications

The applications for this product series tend to be highly customized requiring unique ceramic substrate materials and thicknesses.

Two solder constructions are available to accommodate reflow temperatures up to 230°C or 280ºC. MBX is offered in Au-plated pads or wire bondable posts.

Solder Construction

| Model | Solder Type | Melt Temp |

|---|---|---|

| MBX | (SnSb) Tin Antimony | 232°C |

| HBX | (AuSn) Gold Tin | 280°C |

Ceramic Materials

| Ceramic Material | Thermal Conductivity | Option |

|---|---|---|

| (ALO) Alum Oxide | 24 W/mK | F2 |

| (ALN) Alum Nitride | 170 W/mK | F2N |

Surface Finish Options

| Solder Type | Melt Temp | Option |

|---|---|---|

| Au plating (Hot/Cold Surface) | GG | |

| Non-Metallized Hot and/or Cold face | 11 | |

| Pre-tinning Hot and/or Cold face with 118˚C InSn Solder | 118˚C | 22 |

| Pre-tinning Hot and/or Cold face with 138˚C BiSn Solder | 138˚C | 33 |

| MBX with Ceramic Patterning | MBX with NTC Thermistor | MBX with Posts |

|

|

|

LTS offers hermetic sealing of TEC for non- hermetic packaged optics.

- Protects all inner surfaces of the TEC

- Ultra thin coating that does not impact cooling performance

- Withstands solder mounting temperatures of 200°C for short duration

Coated MBX TECs have been tested under 85C/85%RH conditions for 2,000 hours with minimal (spec <5%) degradation.

Lead Attachment

| Solder Type | Option |

|---|---|

| Au plated pads | W0 |

| Au plated Posts | WP |

Advanced automation with high precision improves TEC assembly methods and repeatability:

- Increases performance, (Qc, ∆T)

- Extends reliability

- Improves cost structure

- Packing density increases exponentially from the standard packing fraction of bulk TEMs