Contents

- Introduction

- Detectors That Benefit from Cooling

- X-Ray Detection and the Need for Thermoelectric Cooling

- ΔT and Cooling Power

- Vacuum Environments and Custom TEC Solutions

- Reliable, Localized Supply Chains

- Efficient Thermoelectric Solutions

- Portable & Bench-Top X-Ray Detection Systems and Their Applications

- Future Developments

- Conclusion

Introduction

X-ray detectors are essential for a wide range of applications, from material analysis to security and medical imaging. However, they must operate at stable, low temperatures to reduce unwanted “thermal noise,” which can blur the signals they capture.

Thermoelectric coolers (TECs) provide a reliable and efficient way to keep X-ray detectors cool. By maintaining temperatures between 253 to 193 Kelvin , TECs help ensure detectors produce clearer, more accurate results. Their compact size and flexibility make TECs ideal for both portable devices and lab-based systems.

Not all x-ray detectors require active cooling. The need for cooling depends on the type of detector and the demands of the application. Many standard digital radiography detectors, for example, operate effectively at room temperature without significant performance loss.

However, for more sensitive detection technologies like semiconductor detectors and charge-coupled devices (CCDs), active cooling can be a key factor in achieving optimal performance.

Detectors that Benefit from Cooling

- High-Purity Germanium (HPGe) detectors used in high-resolution X-ray spectroscopy and nuclear physics research require cooling (often to liquid nitrogen temperatures) to minimize thermal noise and leakage current.

- Silicon Drift detectors (SDDs) used in medical imaging, security, astrophysics and energy-dispersive X-ray spectroscopy (EDS) systems for material analysis are often cooled with thermoelectric devices to improve energy resolution.

- Cadmium Telluride (CdTe) and Cadmium Zinc Telluride (CZT) detectors also used in medical imaging, security, and astrophysics sometimes require thermoelectric cooling to stabilize operation and enhance signal-to-noise ratio.

- CCDs: In fields like X-ray astronomy and synchrotron imaging, CCDs benefit from cooling to reduce dark current and improve signal fidelity

X-Ray Detection and the Need for Thermoelectric Cooling

X-ray detectors analyze material compositions by measuring the X-rays emitted from a sample after it has been energized. Each material emits X-rays at different energy levels, allowing for precise identification and analysis. However, thermal noise can interfere with the detector's ability to capture high-resolution images, making cooling an essential aspect of X-ray detection systems. By cooling the X-ray detector sensors, thermal noise is minimized, enabling the imaging sensor to capture higher resolution images. This improved image resolution is critical for applications involving material analysis of metals, ceramics, glass, and plastics; environmental testing for heavy metal concentrations in soil or water; mining and geology for determining ore composition and mineral content, archeology and art for non-destructive testing of historical artifacts, manufacturing quality control to ensure compliance with standards like RoHS.

TECs are the preferred cooling solution for X-ray detectors due to their efficiency, reliability, and compact size. This is particularly valuable in portable X-ray detection systems, where power consumption, size and performance are critical factors. The performance of TECs in portable X-ray detector cooling applications is measured by their ability to achieve and maintain low temperatures while minimizing power consumption to extend battery life.

ΔT and Cooling Power

In a typical X-ray detector cooling application, TECs must achieve a significant ΔT. For example, an application has a starting temperature of 295 Kelvin (22°C, room temperature) with a target temperature of 215 Kelvin (-58°C), resulting in a temperature differential of 80 Kelvin. This substantial temperature difference highlights the cooling power required from the TECs.

Vacuum Environments and Custom TEC Solutions

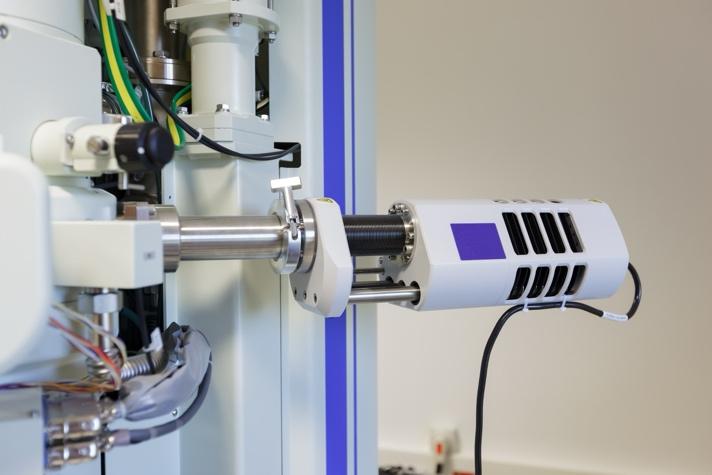

Many X-ray detectors operate in a vacuum, which both protects them from contaminants and enhances TEC efficiency by reducing thermal convection. Under these conditions, TECs can reach lower temperatures with less power. To address the specific needs of X-ray detector manufacturers, custom TEC solutions—such as TEC-to-header assemblies or multi-stage TECs—are utilized.

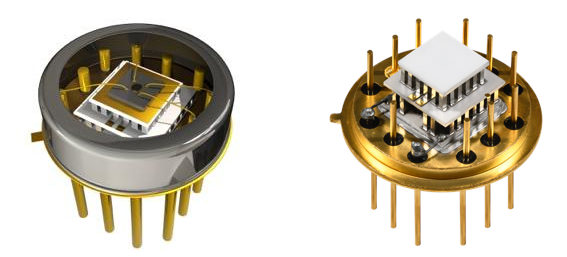

A unique aspect of TECs for X-ray detectors is the integration of the TEC onto a header, typically a TO-8 can. This process involves precise soldering of the TEC to the header minimizing solder voiding to ensure good adhesion and heat dissipation. It also provides a ready-to-use assembly for the X-ray detector manufacturer who can then mount the X-ray detector on top of this assembly and hermetically seal it within the TO can, creating a vacuum environment for optimal performance.

A unique aspect of TECs for X-ray detectors is the integration of the TEC onto a header, typically a TO-8 can. This process involves precise soldering of the TEC to the header minimizing solder voiding to ensure good adhesion and heat dissipation. It also provides a ready-to-use assembly for the X-ray detector manufacturer who can then mount the X-ray detector on top of this assembly and hermetically seal it within the TO can, creating a vacuum environment for optimal performance.

Depending on the required temperature and cooling power, multi-stage TECs are often employed in X-ray detector cooling when desired temperatures are below -40°C. Two-stage TECs can reach temperatures around 215 Kelvin (-58°C) while three-stage TECs can achieve temperatures as low as 193 Kelvin (-80°C). The choice between two-stage and three-stage TECs often involves balancing factors such as cooling performance, power consumption, and size constraints. Multi-stage TECs often require higher voltages and careful current control to achieve optimal performance across all stages. This requires optimizing the TEC design for maximum coefficient of performance (COP).

Reliable, Localized Supply Chains

A dependable, localized supply chain for TECs and TEC assemblies ensures consistent quality, shorter lead times, and responsive technical support. Sourcing components regionally allows manufacturers to collaborate more closely with suppliers, quickly address challenges, and maintain tighter quality control—all critical factors in delivering high-performance X-ray detection systems.

Efficient Thermoelectric Solutions

Products like OptoTEC™ MSX Series of multi-stage TECs provide high-efficiency performance, low power consumption and very cold temperatures, particularly for portable applications. The multistage TECs offer micro footprints on the cold side down to 2.0 x 4.0 mm with height thicknesses down to:

- 3.3 mm for 2 stage

- 3.8 mm for 3 stage

- 4.9 mm for 4 stage

The use of TECs for cooling X-ray detectors offers numerous advantages:

- Improved Signal-to-Noise Ratio - cooling reduces thermal noise, allowing for more precise measurements and higher resolution imaging

- Portability - efficient TEC cooling enables the development of portable X-ray detection systems, expanding the range of possible applications

- Energy Efficiency - especially in vacuum environments, TECs provide efficient cooling with relatively low power consumption

- Precise Temperature Control - TECs allow for accurate and stable temperature regulation, which is crucial for consistent X-ray detector performance

- Compact Size - TECs, particularly when integrated into TO-8 cans, allow for compact X-ray detector designs

- Reliability - with no moving parts, TECs offer high reliability with a long operating life

Customization - TECs can be tailored to specific X-ray detector requirements, optimizing performance for each application

Portable & Bench-Top X-Ray Detection Systems and Their Applications

The demand for portable X-ray detectors has risen, driving the need for efficient, power-saving TEC solutions that support field work and on-site analysis. They provide immediate analysis without transporting samples to a laboratory, conduct non-destructive tests for in-situ examinations and are versatile for a variety of applications from environmental testing to quality control. While portable systems are gaining popularity, bench-top X-ray detection systems remain essential for many research and industrial applications. These systems often require more powerful cooling solutions to achieve lower temperatures, potentially utilizing three- or four-stage TECs.

The demand for portable X-ray detectors has risen, driving the need for efficient, power-saving TEC solutions that support field work and on-site analysis. They provide immediate analysis without transporting samples to a laboratory, conduct non-destructive tests for in-situ examinations and are versatile for a variety of applications from environmental testing to quality control. While portable systems are gaining popularity, bench-top X-ray detection systems remain essential for many research and industrial applications. These systems often require more powerful cooling solutions to achieve lower temperatures, potentially utilizing three- or four-stage TECs.

X-ray detector applications requiring TECs for thermal management solutions can be found across a variety of industries and scientific fields including material analysis, environmental testing, mining and geology, archeology and art, manufacturing and quality control, scientific research, satellite instrumentation, and portable field analysis.

Future Developments

As the field of X-ray detection continues to evolve, several trends are likely to shape the future of TEC cooling in this application:

- Increased Efficiency - ongoing research into thermoelectric materials and designs may lead to even more efficient TECs, further improving the performance of portable X-ray detectors

- Lower Temperatures - advancements in multi-stage TEC technology could enable reaching even lower temperatures, potentially opening new applications for X-ray detection

- Integration of Cooling and Detection - closer integration of TECs with X-ray detector elements may lead to more compact and efficient systems

- Smart Cooling Systems - the incorporation of advanced control algorithms and sensors could optimize cooling performance and energy efficiency in real-time

Expansion of Portable Applications - as TEC-cooled X-ray detectors become more efficient and compact, their use in field applications is likely to expand across various industries.

Conclusion

Thermoelectric coolers are integral to modern X-ray detection, enabling stable, low-temperature operation and higher-quality results. With ongoing advancements and a strong, localized supply chain, TEC-cooled X-ray detectors will continue to shape the future of material analysis, security, medical diagnostics, and scientific research. Learn more about thermoelectric cooling solutions

About Laird Thermal Systems

Laird Thermal Systems develops thermal management solutions for demanding applications across global medical, industrial, transportation, and telecommunications markets. We manufacture one of the most diverse product portfolios in the industry, ranging from active thermoelectric coolers and assemblies to temperature controllers and liquid cooling systems. Our engineers use advanced thermal modeling and management techniques to solve complex heat and temperature control problems. By offering a broad range of design, prototyping, and in-house testing capabilities, we partner closely with our customers across the entire product development lifecycle to reduce risk and accelerate their time-to-market. Our global manufacturing and support resources help customers maximize productivity, uptime, performance and product quality. Laird Thermal Systems is the optimum choice for standard or custom thermal solutions. Learn more by visiting www.lairdthermal.com.

Contact Laird Thermal Systems

Have a question or need more information about Laird Thermal Systems? Please contact us via the website.